Ultra-low temperature FBG temperature sensor - Single point/multi-point FBG thermometer - FBG temperature sensor for liquid oxygen, liquid nitrogen, liquid hydrogen and liquid helium

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

OFSCN® Ultra-low temperature fiber Bragg grating temperature sensor product overview:

Beijing Dacheng Yongsheng Technology Co., Ltd.'s definition of ultra-low temperature:

"Ultra-low temperature" in this document usually refers to a temperature range below tens of degrees below zero, even as low as liquid helium (about 4.2 K or -269 °C) or liquid nitrogen (about 77 K or -196 °C). OFSCN® ultra-low temperature fiber Bragg grating temperature sensor is mainly used in the above temperature range.

OFSCN® ultra-low temperature fiber Bragg grating temperature sensor consists of optical fiber connectors (FC, SC, LC, ST, etc.), low-temperature resistant polymer materials, low-temperature resistant optical fibers, and low-temperature resistant single-point/string fiber Bragg grating (FBG) packaging. It can be customized as an ultra-low temperature radiation-resistant fiber Bragg grating temperature sensor with a certain degree of insulation properties (insulation properties have not been tested).

It is a fiber Bragg grating sensor with the characteristics of low temperature resistance, high sensitivity, fast heat conduction, good accuracy, small size, light weight, waterproof and moisture-proof, corrosion-resistant, and low-voltage insulation.

By using the temperature measurement characteristics of Bragg grating (FBG), this sensor can be inserted, stuck, surface mounted, glued or buried into the structure to be measured for temperature detection and monitoring. It can be widely used in single-point or quasi-distributed temperature measurement in the fields of cryogenic fluids and gases, superconducting materials and devices, aerospace vehicles and components, scientific experimental equipment, special industries and engineering structures, etc.

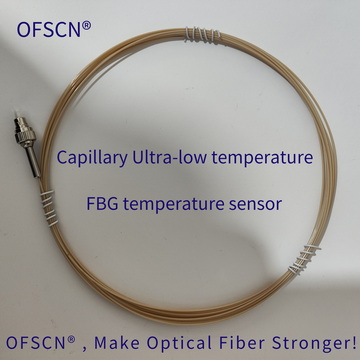

OFSCN® Ultra-low temperature FBG temperature sensor product structure and appearance:

OFSCN® ultra-low temperature fiber Bragg grating temperature sensor can be packaged with either single-point fiber Bragg grating or multi-point fiber Bragg grating string (fiber Bragg grating array); OFSCN® ultra-low temperature fiber Bragg grating temperature sensor appearance is as follows:

|

|

| OFSCN® Ultra-low Temperature FBG Temperature Sensor Overall Appearance | OFSCN® Ultra-low Temperature FBG Temperature Sensor Package |

Overall Parameters of the OFSCN® Ultra-low Temperature FBG Temperature Sensor:

|

Fiber Bragg Grating Temperature Sensor Brand |

OFSCN® |

|

Fiber Bragg Grating Temperature Sensor Product Name |

OFSCN® ultra-low temperature fiber Bragg grating temperature sensor |

|

Fiber Bragg Grating Temperature Sensor Model |

BNCG-SFBG-LT3K-01-FC/APC-10M (Numerous models available, example only) |

| Product Structure: |

Prefabricated fiber connector + 1.0 mm OD package + single-point/multi-point FBG + tail end seal |

|

※ Length Range of Fiber Bragg Grating Temperature Sensor |

10 centimeters to tens of meters (specific length depends on stock availability). |

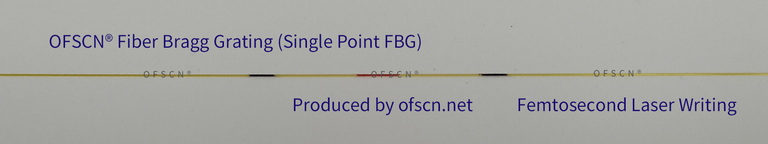

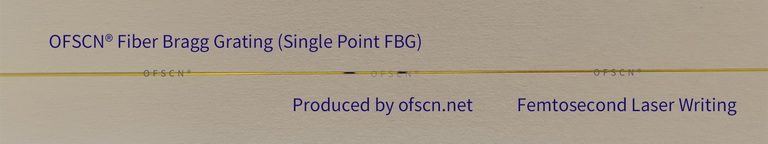

OFSCN® ultra-low temperature FBG temperature sensor's fiber Bragg grating parameters (optional radiation-resistant fiber Bragg grating):

|

|

OFSCN® Ultra-low Temperature FBG Temperature Sensor's Fiber Bragg Grating Example 01 |

|

| OFSCN® Ultra-low Temperature FBG Temperature Sensor's Fiber Bragg Grating Example 02 |

|

| OFSCN® Ultra-low Temperature FBG Temperature Sensor's Fiber Bragg Grating String Example |

Click here to view the parameters of the available FBG/FBG strings for OFSCN® Ultra-low Temperature FBG temperature sensors:

Specifications of the Fiber Connectors Used in the OFSCN® ultra-low temperature FBG temperature sensor:

Note: Fiber connectors are made of metal and are not insulated!

|

|

| OFSCN® Ultra-low Temperature FBG Temperature Sensor Fiber Connector (FC/APC Example) |

|

Fiber Connector Type |

FC、ST、SC、LC |

|

|

End Face Type |

APC |

PC |

|

Ferrule Material |

Ceramic |

|

|

Insertion Loss |

<0.2db |

<0.2db |

|

Return Loss |

>-60db |

>-40db |

|

Storage Environment |

-40℃ to +85℃ |

|

|

Operating Environment |

-40℃ to +75℃ |

|

|

※Optional Fiber Connector |

none |

|

Click here to view the parameters of the available fiber connectors for OFSCN® Ultra-low Temperature Fiber Bragg Grating Temperature Sensors:

120℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

200℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

300℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - APC

Composition of OFSCN® Ultra-low Temperature FBG Temperature Sensing System:

OFSCN® Ultra-low Temperature Fiber Bragg Grating Temperature Sensing System consists of OFSCN® Fiber Bragg Grating Temperature Sensors, OFSCN® Fiber Optic Patch Cords and OFSCN® Fiber Bragg Grating Interrogators (Demodulators), which together constitute the Fiber Bragg Grating Temperature Monitoring System.

OFSCN Fiber Bragg Grating (Fiber Optic Grating) Temperature Sensor Overview Video:

Features of OFSCN® Ultra-Low Temperature Fiber Bragg Grating (FBG) Temperature Sensor:

- Ultra-Low Temperature Capability: Specifically engineered for cryogenic temperatures, including liquid helium and liquid nitrogen environments.

- Compact and Lightweight: Features a small size and light weight, making it easy to integrate into various systems.

- High Sensitivity and Accuracy: Provides precise and accurate temperature measurements.

- Fast Thermal Response: Designed for quick thermal conductivity, allowing for rapid temperature detection.

- Durable and Robust: Encapsulated in a 1.0 mm outer diameter low-temperature resistant polymer material, ensuring durability.

- Waterproof and Moisture-Proof: Suitable for use in demanding and humid environments.

- Corrosion Resistance: Offers good resistance to corrosive substances.

- Low Voltage Insulation: Possesses a degree of insulation properties (though specific insulation characteristics are not fully tested).

- Customizable: Can be customized as an ultra-low temperature radiation-resistant fiber optic grating temperature sensor.

- Single-Point or Multi-Point Sensing: Available with either a single Fiber Bragg Grating (FBG) or multiple FBGs in an array (fiber optic grating string) for quasi-distributed temperature measurement.

- Flexible Installation: Can be embedded, clamped, surface-mounted, glued, or buried into the structure under test.

Possible Application Scenarios and Industries of OFSCN® Ultra-Low Temperature Fiber Bragg Grating (FBG) Temperature Sensors:

The OFSCN® ultra-low temperature fiber optic grating temperature sensor is suitable for single-point or quasi-distributed temperature measurement in a wide range of critical applications.

Application Scenarios Examples of OFSCN® Ultra-Low Temperature Fiber Bragg Grating Temperature Sensors:

- Cryogenic Fluid and Gas Systems:Monitoring of liquid natural gas (LNG), liquid oxygen (LOX), liquid hydrogen (LH2), and other industrial cryogenic gases.Temperature monitoring in cryogenic storage tanks, pipelines, and transfer systems.

- Superconducting Materials and Devices:Temperature measurement in superconducting magnets (e.g., in MRI machines, particle accelerators).Monitoring of superconducting power cables and devices to ensure optimal operating temperatures.Research and development of new superconducting materials.

- Aerospace and Aviation:Temperature sensing in cryogenic propulsion systems for rockets and spacecraft.Monitoring of liquid fuel tanks and lines in space vehicles.Temperature control in space simulation chambers.Applications in satellite components and cryogenic coolers for space instruments.

- Scientific Experimental Devices:Temperature monitoring in laboratory cryostats and dilution refrigerators.Research in low-temperature physics and chemistry.Applications in quantum computing and cold atom research.Monitoring in particle accelerators and detectors (e.g., CERN).

- Special Industrial and Engineering Structures:Temperature monitoring in large-scale cryogenic infrastructure projects.Detection of cold spots or leaks in cryogenic insulation.Structural health monitoring of materials exposed to extreme cold environments.Applications in food processing and preservation where ultra-low temperatures are required.

Industry Examples of OFSCN® Ultra-Low Temperature Fiber Bragg Grating (FBG) Temperature Sensors:

- Industrial Production:For precise temperature control and monitoring in factories and plants.

- Electric Power:Monitoring transformers, cables, generators, and other critical power infrastructure.

- Railway:Temperature detection in tracks, train components, and signaling systems.

- Military:Applications requiring robust and reliable temperature sensing in demanding conditions.

- Aerospace:Monitoring temperatures in aircraft structures, engines, and space vehicles.

- Oil & Gas:Temperature sensing in pipelines, wells, and storage facilities.

- Chemical Industry:Monitoring temperatures in reactors, tanks, and pipelines where corrosive materials are present.

- Renewable Energy:Temperature monitoring in solar panels, wind turbine components, and geothermal systems.

- Research & Development:Used in laboratories for various temperature-sensitive experiments and tests.

DCYS is a professional manufacturer of Ultra-low temperature FBG temperature sensor, providing Ultra-low temperature FBG temperature sensor principle, package design, working temperature range, advantages and disadvantages, installation and applications, calibration test report; our brand of Ultra-low temperature FBG temperature sensor is "OFSCN". Bulk purchase, better price!