Polyimide Recoated Fiber Bragg Grating - Fiber Optic Grating - Fiber Bragg Grating Array - UV Photomask Written

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

Product Aliases: UV mask FBG, Polyimide coated FBG, high-temperature FBG, Bare FBG.

This product is a standard stock UV photomask-written FBG, coated with polyimide, and consists of high-temperature (low-temperature) resistant Fiber Bragg Grating (FBG) or Fiber Bragg Grating Array (FBGs). It can be purchased individually or as an accessory for the OFSCN® Series Fiber Bragg Grating Temperature Sensors (FBG thermometers), Fiber Bragg Grating Strain Sensors (FBG strain gauges), and Fiber Bragg Grating Stress Sensors (FBG load cells).

The provided FBG parameters are for reference only. After being made into a Fiber Bragg Grating Sensor (FBG sensor), the parameters may slightly vary. Customization is available to meet different user requirements.

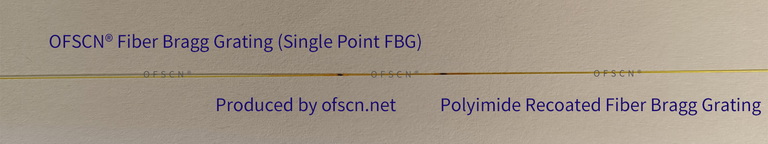

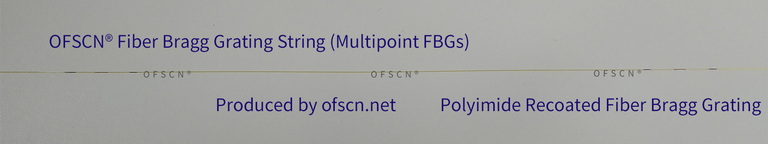

Video demonstration of the physical appearance of FBG:

Parameters of the Polyimide-Recoated Fiber Bragg Grating (FBG):

|

Parameter List |

Value |

|

Tail Fiber + Fiber Bragg Grating (FBG) Length |

Length is determined by customer specifications |

|

Fiber Bragg Grating (FBG) Operating Temperature Range |

-200°C to 300°C |

|

Available strain range |

Maximum 10000με (micro strain) |

|

Fiber Type for Fiber Bragg Grating (FBG) |

Polyimide-coated fiber resistant to high and low temperatures. |

|

Coating for Fiber Bragg Grating (FBG) |

Polyimide |

|

Fiber Bragg Grating (FBG) Wavelength Deviation |

+/-0.3nm |

|

Multi-point Capability |

Customizable FBG array |

|

Fiber Bragg Grating (FBG) type |

Default is a uniform Fiber Bragg Grating. |

|

Fiber Bragg Grating (FBG) Length |

3 ~10mm |

|

Fiber Bragg Grating (FBG) Central Wavelength |

Standard stock in the C-band (1525 ~ 1565nm), extendable to 1510 ~ 1590nm. |

|

Fiber Bragg Grating (FBG) Bandwidth @ 3dB |

≤0.3nm (for standard 10mm length) |

|

Fiber Bragg Grating (FBG) SLSR Suppression Ratio |

≥15db |

|

Fiber Bragg Grating (FBG) Reflectivity |

Customizable, not exceeding 100%. |

|

Fiber Bragg Grating (FBG) Operating Temperature |

-200°C to 300°C |

OFSCN® Polyimide-Recoated high-temperature FBG Fiber Parameters:

Click here to see the parameters for available OFSCN® Polyimide-Recoated high-temperature FBG fibers:

Attachment 1:

|

Attachment 2:

|

Features of OFSCN® Polyimide-Recoated high-temperature FBG:

- Excellent High-Temperature Resistance: The polyimide coating can withstand temperatures up to 300℃ or even higher, far exceeding conventional fiber coatings. This makes it ideal for long-term stable operation in high-temperature environments.

- Compact Size and Chemical Resistance: The thin polyimide coating results in a smaller fiber diameter. It also provides excellent chemical resistance, allowing for stable operation in harsh environments like oil and gas, and chemical industries.

- Advanced Manufacturing Process: The UV mask method ensures high precision and consistency in the FBGs, enhancing product reliability.

- Flexible Application: The customizable grating lengths of 3mm, 5mm, and 10mm enable customers to tailor the product to their specific measurement needs.

Possible Application Scenarios and Industries of OFSCN® Polyimide-Recoated high-temperature FBG:

Given its outstanding high-temperature and chemical resistance, this FBG/FBG array has broad prospects in various specialized application scenarios.

Application Scenarios Examples of OFSCN® Polyimide-Recoated high-temperature FBG:

Measurements in High-Temperature Environments:

-

- Packaged for Use: It can be used as the core sensing element in packaged high-temperature sensors. For example, in aerospace, oil and gas exploration, and nuclear power plants, it can monitor parameters like temperature, stress, and strain.

- Used Directly Without Packaging: In laboratory settings, it can be used directly to measure parameters like stress, strain, and vibration of high-temperature equipment or materials for scientific research and high-temperature testing.

- Structural Health Monitoring in Harsh Environments:

- Chemical Industry: Used for monitoring strain and temperature changes in pipes and storage tanks within corrosive environments.

- Geothermal Exploration: Used to monitor temperature and pressure inside geothermal wells to assess geothermal resources.

- Aero-Engine Testing: Installed directly on engine components to monitor strain and vibration during high-temperature, high-speed operation.

DCYS is a professional polyimide FBG manufacturer, providing polyimide FBG parameters, customization, wavelength, usage and other information; polyimide FBG brand is "OFSCN". Bulk purchase, better price!