Installation Fixture - FBG Sensor Engineering Fixture - FBG Strain Stress Displacement Pressure Sensor Construction Installation - Example

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

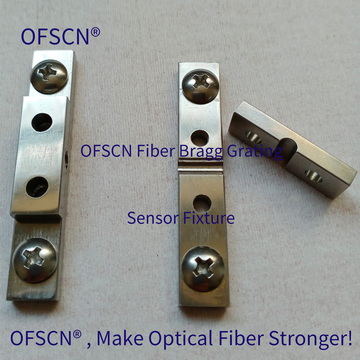

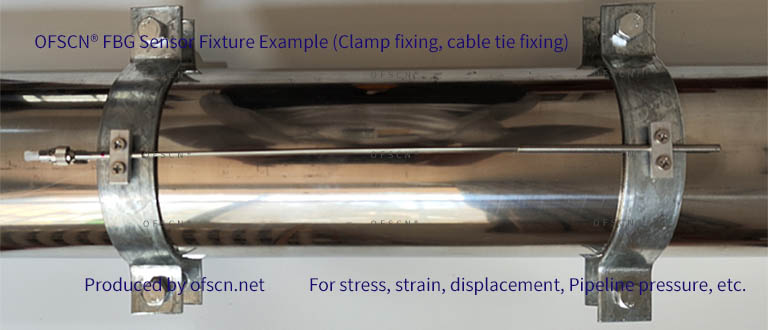

This product is a supporting installation fixture for OFSCN® fiber bragg grating (FBG) sensors, produced by DCYS. It is used for the installation and fixation of OFSCN® FBG strain sensors, FBG stress sensors, FBG displacement sensors, FBG Pipeline Pressure Sensor, and other products such as serially connected FBG temperature sensors. The fixture has the characteristics of small deformation, easy use and flexible installation. In addition to conventional screw installation, it can also be installed by welding, gluing(surface mounting), cable tie binding and clamps.

The welding and gluing installation methods for OFSCN® capillary series FBG sensors are not demonstrated here. The conventional screw installation method is described as follows:

1、Surface Preparation and Marking

Clean the installation surface thoroughly. Place the long fixing plate on the installation surface and mark the holes at both ends with a marker pen. Use a drill to create holes at the marked positions and insert plugs, then flatten them with a hammer.

Apply adhesive (this step can be omitted) to the contact area between the long fixing plate and the installation surface. Press the long fixing plate onto the surface (ensure that the holes in the long fixing plate align with the holes in the plugs), and tighten the screws. Proceed to the next step after the adhesive has cured.

2、Placement and Fixation of FBG Sensors

|

Position the tail handle of the OFSCN® capillary seamless steel tube FBG sensor in the semicircular groove of the long fixing plate, and press the semicircular groove of the short fixing plate onto the sensor's tail handle. Finally, secure them with screws, clamping the tail handle of the OFSCN® capillary seamless steel tube FBG sensor (on the side closer to the fiber core) between the two fixing plates

3、Completed Installation

|

Repeat the same process to secure the other end of the OFSCN® capillary seamless steel tube FBG sensor to complete the installation.

4、Important Notes during Installation

The OFSCN® capillary seamless steel tube FBG sensor usually has a certain pre-tension when it leaves the factory. Therefore, excessive pre-tension is not required during the installation process, but excessive pressure should also be avoided. Hence, it is important to straighten and secure the FBG sensor as much as possible during the installation process.

By following these steps, accurate measurement of physical quantities such as strain, stress, and temperature can be ensured for the OFSCN® capillary seamless steel tube FBG sensor at both ends.

OFSCN® series fiber optic Bragg grating strain sensor fixture customization and installation example:

|

| OFSCN® Series FBG Strain Sensor Gluing and Surface Mounting Installation Examples (Customized Fixtures) |

|

| OFSCN® Series FBG Strain Sensor Bolt-Fixed and Welded Installation Examples (Customized Fixtures) |

|

| OFSCN® series FBG strain sensor pipe clamp installation example (customized clamp), pipe longitudinal measurement |

|

| OFSCN® series FBG strain sensor pipeline strain installation example (custom fixture), pipeline annular strain, pressure measurement (01) |

|

| OFSCN® series FBG strain sensor pipeline strain installation example (custom fixture), pipeline annular strain, pressure measurement (02) |

DCYS is a professional manufacturer of FBG sensor installation and fixing fixtures, providing information such as the installation method, fixing method, Pipeline installation diagram of fixtures; the brand of fixtures as "OFSCN". Bulk purchase, better price!