3% to 40% deformation fiber Bragg grating strain sensor - Ultra-large range FBG strain gauge - Measuring range of 30000με to 400000με

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

Product Alias: Ultra-high-range fiber Bragg grating length sensor, ultra-high-range fiber Bragg grating displacement sensor, FBG crack gauge, crack monitor.

Product Function: It is used for monitoring strain and displacement of various cracks, potential landslides, and deformations. The product length is customizable, and the strain range can be customized from 30,000 με (3% strain) to 400,000 με (40% strain).

Principle of OFSCN® Ultra-High-Range Fiber Bragg Grating Strain Sensor:

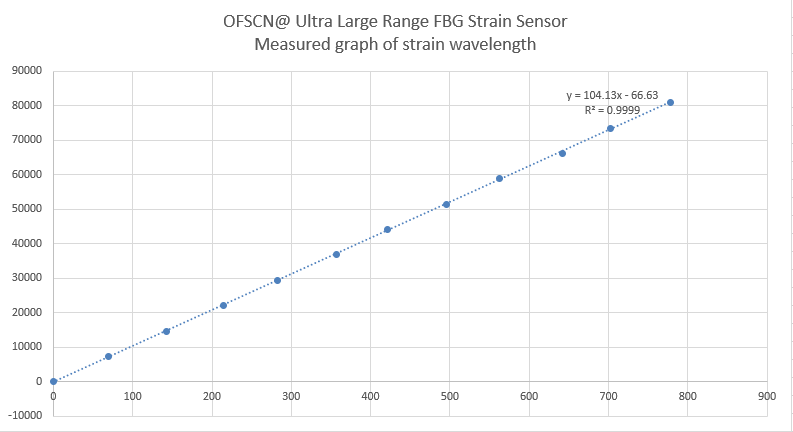

The OFSCN® ultra-high-range fiber bragg grating strain sensor is a customized development based on DCYS's FBG strain sensor. The goal is to meet the application requirements for larger changes in strain, deformation, displacement, length, and other physical quantities.

|

| The sensor length shown in the diagram is 30 cm, with the Y-axis unit in με (microstrain) and the X-axis unit in pm (picometer) |

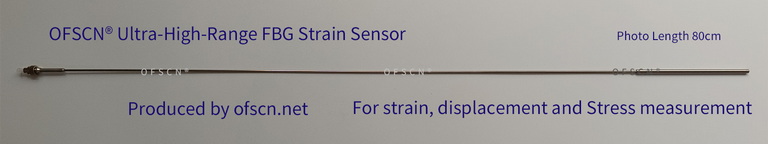

Structure and Composition of OFSCN® Ultra-High-Range Fiber Bragg Grating Strain Sensor:

The OFSCN® ultra-high-range fiber bragg grating strain sensor consists of fiber connectors, all-metal stainless seamless steel tubes/high-polymer elastic materials, FBG, and other packaging components. When combined with a FBG demodulator, it can form an ultra-high-range FBG strain sensing system or a high range FBG displacement sensing system.

Operating Environment and Application Industries of OFSCN® Ultra-High-Range Fiber Bragg Grating Strain Sensor:

OFSCN® ultra-high-range fiber Bragg grating strain sensors are commonly used in various environments, including dams, bridges, tunnels, large crane booms, surfaces inside and outside buildings, concrete surfaces and interiors, highway roadbeds, tunnels, and areas prone to landslides. They can be used in fields such as transportation, tunnels, large-scale machinery, giant antennas, environmental protection, and advanced scientific research.

Measurement Range and Product Details of OFSCN® Ultra-High-Range Fiber Bragg Grating Strain Sensor:

The measurement range of OFSCN® ultra-high-range fiber bragg grating strain sensors can be customized, with a minimum range greater than 30,000 με (3% strain), typical ranges of 100,000 με (10% strain), 200,000 με (20% strain), and 300,000 με (30% strain). The structure of the product varies depending on the customized range.

Advantages of OFSCN® Ultra-High-Range Fiber Bragg Grating Strain Sensor:

Compared to traditional resistive strain gauges, OFSCN® ultra-high-range FBG strain sensors enable continuous real-time online strain measurement. They are not affected by environmental conditions such as air quality (haze, rain, snow, obstruction), ensuring accurate measurements with rapid response (millisecond-level response).

Compared to various electric signal strain sensors based on current, resistance, voltage, capacitance, and other technologies, OFSCN® ultra-high-range FBG strain sensors are based on fiber optic communication and fiber optic sensing. Therefore, they are not affected by electromagnetic interference and can work in various strong and weak electromagnetic environments.

Compared to traditional resistive strain gauges, OFSCN® ultra-high-range FBG strain sensors have a longer length, allowing for the measurement of large displacements and a wider range of environmental or object monitoring. This helps save on the number of sensors used and reduces costs.

OFSCN® ultra-high-range FBG strain sensors are digital, recordable, and network-enabled sensors. They are easy to deploy and have flexible lengths. The strain information can be monitored without the need for visual observation. The FBG strain sensing system formed by these sensors can monitor strain information in large spaces, over long distances, and across multiple targets, providing a wide spatial coverage range.

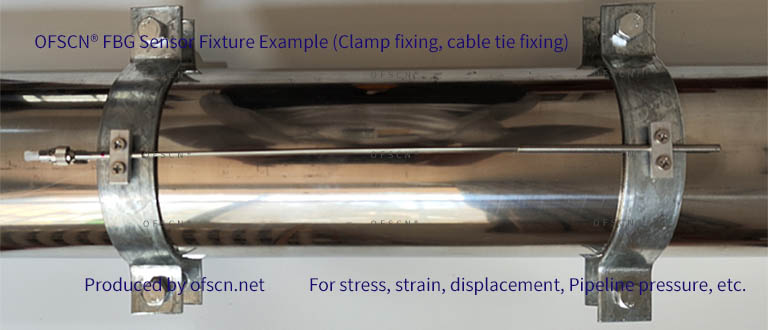

OFSCN® series fiber optic Bragg grating strain sensor fixture customization and installation example:

|

| OFSCN® Series FBG Strain Sensor Gluing and Surface Mounting Installation Examples (Customized Fixtures) |

|

| OFSCN® Series FBG Strain Sensor Bolt-Fixed and Welded Installation Examples (Customized Fixtures) |

|

| OFSCN® series FBG strain sensor pipe clamp installation example (customized clamp), pipe longitudinal measurement |

Composition of OFSCN® Ultra-high-range Fiber Bragg Grating Strain Sensing System:

OFSCN® Fiber Bragg Grating Strain Sensing System consists of OFSCN® Fiber Bragg Grating Strain Sensor, OFSCN® Sensor Mounting Fixture and OFSCN® Fiber Bragg Grating Demodulator, which together constitute the Fiber Bragg Grating Strain Monitoring System.

DCYS is a professional fiber grating strain sensing system manufacturer, providing FBG strain gauge principle, packaging design scheme, application information in dams, mine collapses, roadbed settlements, landslides, crane booms and other fields; our FBG strain sensor's brand is "OFSCN". Bulk purchase, better price!