Fiber Bragg Grating Stress Sensor - FBG Stress Gauge - Bolt and Anchor Rod Stress Detection

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

This product is a FBG stress sensor (FBG stress gauge) that is encapsulated in seamless steel tubes or polymer materials for stress measurement. It can be designed as a single-ended structure for insertion into the tested object for stress measurement, or as a double-ended structure for immersion or surface attachment to enable multiple-point stress measurement in series. The structure of this product is the same as various fiber optic grating strain sensors.

Principle of FBG Stress Sensor:

The FBG stress sensor is a derivative application of the OFSCN® FBG Strain Sensor. The relationship between them is as follows: Stress of the tested object = Elastic modulus of the tested object × Strain. Therefore, the structure of the FBG stress sensor is the same as the OFSCN® FBG Strain Sensor. However, since the tested materials may vary for customers who purchase FBG stress sensors, the calibration formula is given in terms of micro-strain and corresponding wavelength.

Structure and Composition of FBG Stress Sensor:

OFSCN® Capillary FBG Stress Sensor (FBG stress gauge) consists of fiber optic connectors (FC, SC, LC, ST, etc.), different types of encapsulation materials, and FBG. When used together with FBG demodulators, it forms a FBG stress sensing system.

It can be widely used for single-point or distributed stress monitoring and measurement (including tension and compression) in industrial equipment, bolts, parts, cranes, concrete, railways, military equipment, aerospace, and other fields.

Deployment Methods for FBG Stress Sensor:

OFSCN® Capillary FBG Stress Sensor has the characteristics of small size, light weight, high tensile strength, high compressive strength, water resistance, moisture resistance, and full sealing. By utilizing the strain characteristics of FBG, the sensor can be inserted, clamped, attached to the surface, bonded, or embedded into the tested structure for stress detection and monitoring

When combined with other tested objects, the OFSCN® FBG Stress Sensor can be used as an anchor rod stress sensor, surrounding rock stress sensor, borehole stress sensor, steel support stress sensor, blade stress sensor, blast stress sensor, and more.

The OFSCN® Capillary FBG Stress Sensor can be installed by directly fixing and clamping both ends, welding, bundling, adhesive surface mounting, adhesive encapsulation after insertion into the tested object, or direct installation in concrete, among other methods. In some special applications, special fixtures can be designed to assist in displacement measurement

Usage Environment and Application Industries of FBG Stress Sensor:

OFSCN® Capillary FBG Stress Sensors are commonly used in various environments such as dams, bridges, tunnels, large crane booms, large machinery and equipment, interior and exterior surfaces of buildings, concrete surfaces and interiors, highway roadbeds, tunnels, and locations prone to landslides. They can also be used for testing various new materials.

Usage Environment and Application Industries of FBG Stress Sensor:

Depending on the characteristics of the tested material or object and the formula "Stress of the tested object = Elastic modulus of the tested object × Strain," the following fiber optic grating strain sensors can be used for stress measurement:

1、Fiber Bragg Grating Strain Sensor - FBG Strain Gauge - Metal Encapsulation, Measuring Range: 2500με

Advantages of FBG Stress Sensor:

Compared to stress sensors based on vibrating wires, the OFSCN® Capillary FBG Displacement Sensor uses the displacement of the internal FBG as a reference for displacement detection. It is not affected by environmental conditions such as air quality (haze, rain, snow, obstruction), ensuring accurate testing and rapid response (millisecond-level response).

Compared to piezoelectric stress sensors based on current, resistance, voltage, capacitance, and other technologies, the OFSCN® Capillary FBG Stress Sensor is based on fiber optic communication and sensing. Therefore, it is immune to electromagnetic interference and can operate in various strong and weak electromagnetic environments.

Compared to stress sensors based on various PCB circuits, the OFSCN® Capillary FBG Stress Sensor can be customized in length, offering flexibility in usage with both long and short lengths. It can monitor a wide range of environments or objects, saving the number and cost of sensors used.

The OFSCN® Capillary FBG Stress Sensor is a digital, recordable, and network-enabled sensor. Changes in length and displacement can be monitored without the need for visual observation. The FBG stress sensing system can monitor length changes and displacement information over large spaces, long distances, and multiple targets, with a wide coverage range.

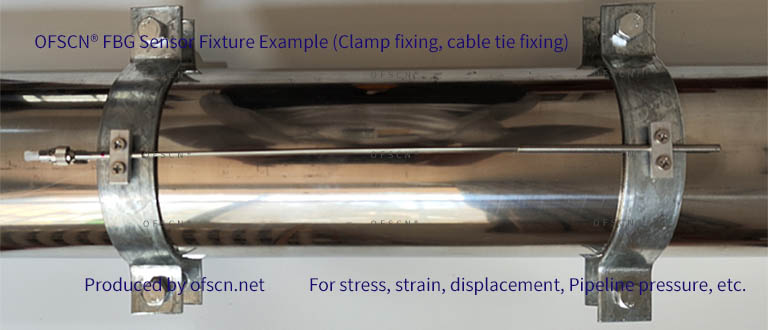

OFSCN® series fiber optic Bragg grating strain sensor fixture customization and installation example:

|

| OFSCN® Series FBG Strain Sensor Gluing and Surface Mounting Installation Examples (Customized Fixtures) |

|

| OFSCN® Series FBG Strain Sensor Bolt-Fixed and Welded Installation Examples (Customized Fixtures) |

|

| OFSCN® series FBG strain sensor pipe clamp installation example (customized clamp), pipe longitudinal measurement |

Composition of OFSCN® Fiber Bragg Grating Stress Sensing System:

OFSCN® Fiber Bragg Grating Stress Sensing System consists of OFSCN® Fiber Bragg Grating Stress Sensor, OFSCN® Sensor Mounting Fixture and OFSCN® Fiber Bragg Grating Demodulator, which together constitute the Fiber Bragg Grating Stress Monitoring System.

DCYS is a professional FBG stress sensor manufacturer, providing information on the principle of fiber bragg grating stress sensors, structural design schemes, working accuracy, installation and use, temperature compensation, and calibration test reports; the brand of FBG stress sensor is "OFSCN". Bulk purchase, better price!