6000με Fiber Bragg Grating Strain Sensor - FBG Strain Gauge - Metal Encapsulation - High Temperature FBG Strain Sensor

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

The product is a fiber Bragg grating strain sensor (FBG strain gauge) encapsulated in high elastic alloy tube, used for strain measurement. In most cases, it is a single-segment single-ended structures, or it can be produced as a multi-segment single-ended structure. In a few cases, it can also be a double-ended structure. The sensor can be customized as radiation-resistant fiber Bragg grating strain sensor or high-temperature resistant fiber Bragg grating strain sensor. The deployment method of the product depends on the supporting fixtures, which can be directly inserted into the test object, or installed by surface welding with corresponding fixtures, bolted with drilled holes for fixation, adhesive surface mounting, tied with straps for fixation, or fixed with clamps, among various installation methods. This product is a basic structural product, which can be calibrated as a FBG displacement sensor, or used as a FBG stress sensor.

OFSCN® 6000με FBG Strain Sensor Product Summary:

The OFSCN® 6000με FBG Strain Sensor (FBG strain gauge) is composed of fiber optic connectors (FC, SC, LC, ST, etc.), high elastic alloy tubes, and single-point/Multi-point FBG encapsulation.

It can also be customized as radiation-resistant FBG strain sensor or high-temperature resistant FBG strain sensor.

This product features a small size, lightweight, high tensile and compressive strength, waterproof, moisture-proof, and fully sealed characteristics. By utilizing the strain characteristics of the FBG, this sensor can be inserted, clamped, surface-mounted, glued, or embedded into the measured structure to perform strain detection and monitoring.

It can be widely used in various fields such as industrial equipment, bolts, components, cranes, concrete, railways, military equipment, aviation, aerospace, etc., for single-point or multi-point quasi-distributed strain monitoring and measurement.

|

|

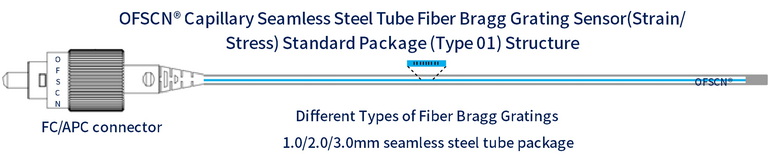

Structure Diagram of OFSCN® Capillary Seamless Steel Tube FBG Strain Sensor (single-ended) |

Overview of OFSCN® 6000με Fiber Bragg Grating Strain Sensors:

|

Brand |

OFSCN® |

|

Product Name |

OFSCN® 6000με Fiber Bragg Grating Strain Sensor |

|

Product Model |

OFSCN-FBG-SH085-10/11-FC-FC-20CM (multiple models available, example only) |

|

Product Structure: Prefabricated fiber optic connector + 1.1mm high elastic alloy tube + single-point Fiber Bragg Grating (Multi-point Fbgs) + Tail end fixed point sealing |

|

※Length Range |

From 10 centimeters to 2 meter (Other lengths are customizable) |

Fiber Bragg Grating Parameters:

|

|

Fiber Bragg Grating Type |

UV/FS/LPFG (Depending on the required strain range) |

|

Center Wavelength |

Conventional range of 1525nm to 1565nm (Other wavelengths can be customized) |

|

Reflectivity |

10% to 99% |

|

Strain |

To be discussed directly |

|

Strain Range |

6000 με (microstrain) |

|

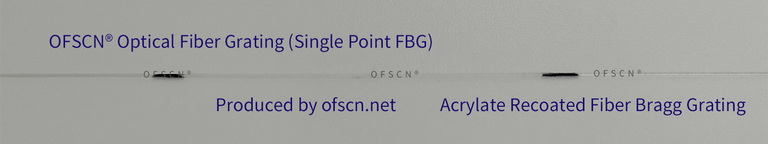

※ Optional Fiber Bragg Grating |

Various options available, to be discussed directly |

OFSCN® 6000με FBG Strain Sensor's Connector Specifications:

|

|

Fiber Optic Connector Type |

FC |

|

|

End Face Type |

APC |

PC |

|

Core Material |

Ceramic | |

|

Insertion Loss |

<0.2db |

<0.2db |

|

Return Loss |

>-60db |

>-40db |

|

Storage Environment |

-40℃ to +85℃ |

|

|

Operating Environment |

-40℃ to +75℃ |

|

|

※ Optional Fiber Optic Connector |

FC/APC, FC/PC options available for high-temperature resistance connectors. Temperature resistance depends on inventory. |

|

Parmerters of Armor for Finished OFSCN® 6000με FBG Sensor :

|

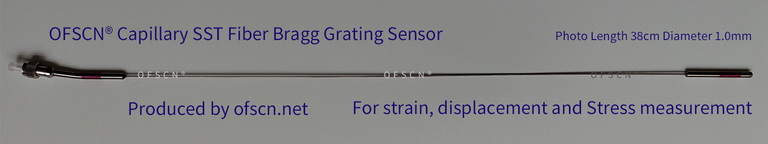

| Physical diagram of OFSCN® 6000με Fiber Bragg Grating Strain Sensor (1.1mm diameter FBG strain gauge) |

|

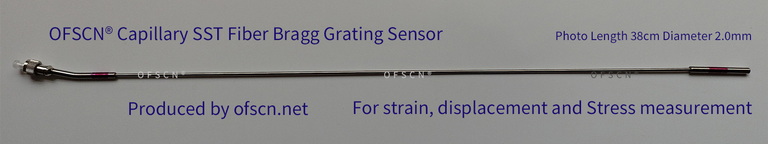

| Physical diagram of OFSCN® 6000με Fiber Bragg Grating Strain Sensor (2.0mm diameter FBG strain gauge) |

|

Armor type for FBG sensor |

OFSCN® 6000με fiber Bragg grating strain sensor, standard packaging |

|

Armor diameter for FBG sensor |

1.0/1.1/2.0/3.0mm |

|

Material of Seamless Steel Tube Used in the Fiber Bragg Grating Sensor |

high elastic alloy |

|

Wall Thickness of Seamless Steel Tube Used in the Fiber Bragg Grating Sensor |

Determined based on actual requirements |

|

Weight of Seamless Steel Tube Used in the Fiber Bragg Grating Sensor |

Determined based on actual requirements |

|

Tensile Strength of the Fiber Bragg Grating Sensor |

Determined based on actual requirements |

|

Lateral Pressure Resistance of the Fiber Bragg Grating Sensor |

Determined based on actual requirements |

|

Compressive Strength of the Fiber Bragg Grating Sensor |

Determined based on actual requirements |

|

※ Optional Armor of the Fiber Bragg Grating Sensor |

Sensor diameter (0.9mm/2.0mm/3.0mm), non-conventional corrosion-resistant solutions. |

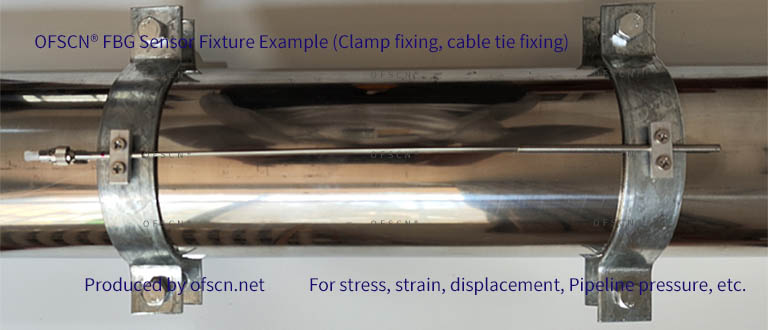

OFSCN® series fiber optic Bragg grating strain sensor fixture customization and installation example:

|

| OFSCN® Series FBG Strain Sensor Gluing and Surface Mounting Installation Examples (Customized Fixtures) |

|

| OFSCN® Series FBG Strain Sensor Bolt-Fixed and Welded Installation Examples (Customized Fixtures) |

|

| OFSCN® series FBG strain sensor pipe clamp installation example (customized clamp), pipe longitudinal measurement |

|

| OFSCN® series FBG strain sensor pipeline strain installation example (custom fixture), pipeline annular strain, pressure measurement (01) |

|

| OFSCN® series FBG strain sensor pipeline strain installation example (custom fixture), pipeline annular strain, pressure measurement (02) |

Composition of OFSCN® 6000με Fiber Bragg Grating Strain Sensing System:

OFSCN® Fiber Bragg Grating Strain Sensing System consists of OFSCN® Fiber Bragg Grating Strain Sensor, OFSCN® Sensor Mounting Fixture and OFSCN® Fiber Bragg Grating Demodulator, which together constitute the Fiber Bragg Grating Strain Monitoring System.

DCYS is a professional FBG strain sensor manufacturer, providing fiber bragg grating strain sensor principle, structural design, working accuracy, installation and usage, temperature compensation, calibration experiment report and other information; FBG strain sensor brand is "OFSCN ". Bulk purchase, better price!