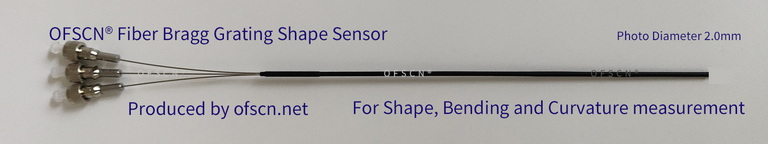

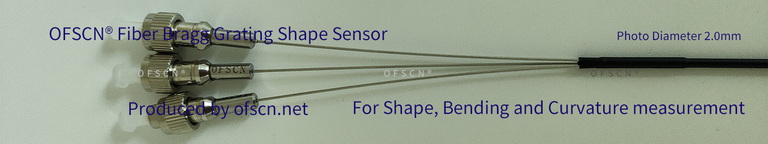

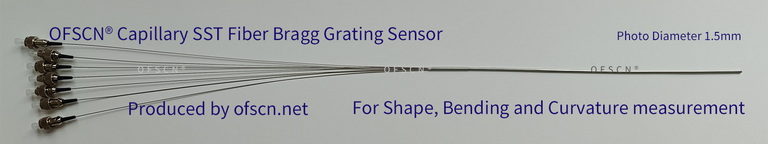

Fiber Bragg Grating Shape Sensor - FBG Curvature Sensor - Three-dimensional Bending and Multi-angle Measurement

- Currency: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD and CHF; DKK; PLN; SEK; AED; THB

- Brand Name: OFSCN® Unbranded products are available.

- Availability: In stock and PreOrder

1. Product Overview

The OFSCN® Fiber Optic Grating Shape Sensor is a new generation of high-precision flexible sensor developed based on Distributed Fiber Bragg Grating (FBG) technology. It is specifically designed for the real-time perception and reconstruction of three-dimensional shapes. The product has been upgraded to its Third Generation, featuring a compact structure, high precision, strong immunity to electromagnetic interference, and robust adaptability to harsh environments. It is widely used in fields such as medical device navigation, industrial structural health monitoring, robotics, and aerospace.

2. Technical Features

2.1 Sensing Principle and Architecture

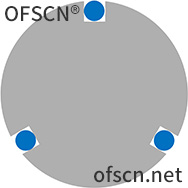

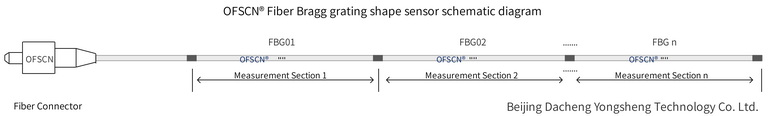

The sensor utilizes the industry-standard 3 FBG string scheme to achieve high-precision 3D shape measurement. These three FBG strings are longitudinally placed along the circumference of the substrate material, uniformly spaced at 120 degrees apart. By measuring the axial strain on each fiber string and applying curvature calculations, the overall shape of the sensor can be precisely determined.

|

|

2.2 Core Materials and Packaging

- Substrate Material (Inner Layer): The default core substrate is an elastic alloy rod, providing excellent mechanical stability and elastic recovery. Customers may also select an elastic polymer rod as the substrate material for applications requiring higher flexibility.

- Protective Casing (Outer Layer): A polymer tube is the default outer layer, protecting the sensor's substrate material and ensuring good durability and isolation in complex operating environments.

2.3 Sensing Unit and Connection

- Sensing Unit: Each FBG string is customized with multiple FBG sensing segments which collectively form the core sensing unit of the shape sensor, enabling quasi-distributed measurement.

- Pigtail and Connector: The pigtails of the three FBG strings are reinforced and brought out using seamless steel tubes, offering superior protection against bending and tensile stress. The fiber connector type is standardized to FC/APC to ensure low back reflection and reliable connectivity.

2.4 Demodulation and Algorithm

Note: The OFSCN® Fiber Optic Grating Shape Sensor currently provides the hardware component only and does not include a matching demodulation algorithm. Users are required to complete the shape demodulation and calculation independently.

3. Key Specifications

|

Parameter |

Default Specification |

Customization Range |

Notes |

|

Product Brand |

OFSCN® |

- |

- |

|

Product Name |

Fiber Optic Grating Shape Sensor |

- |

- |

|

Product Generation |

Third Generation |

- |

Uses 3 FBG strings scheme |

|

Sensing Scheme |

3 FBG strings |

- |

Arranged 120 degrees circumferentially |

|

Substrate Material (Inner Layer) |

Elastic Alloy Rod |

Elastic Polymer Rod |

Default is Elastic Alloy Rod |

|

Protective Casing (Outer Layer) |

Polymer Tube |

- |

Default configuration |

|

Default Sensor Total Length |

25 CM |

Other Lengths |

Includes sensing unit and pigtail lead-out section |

|

Default Sensing Unit Length |

20 CM |

Other Lengths |

FBG measurement region length |

|

Default Sensor Diameter |

2 mm |

Other Diameters |

- |

|

Pigtail Encapsulation |

Seamless Steel Tube |

- |

- |

|

Fiber Connector Type |

FC/APC |

- |

- |

|

Operating Temperature |

-20℃ - 50℃ |

- |

Standard use temperature |

|

Storage Temperature |

-40℃ - 75℃ |

- |

- |

|

Demodulation Algorithm |

None (Not Included) |

To be completed by the customer |

Sensor hardware only |

Note: Custom specifications require evaluation by sales or technical personnel.

Demonstration of Fiber Bragg Grating Shape Sensor Applications:

DCYS is a professional FBG shape/three-dimensional bending/curvature change sensing system manufacturer, providing FBG shape sensor principles, packaging design solutions, and applications in new material testing, robots, manipulators, aerospace and other fields Information; Our FBG shape sensor brand is "OFSCN". Bulk purchase, better price!