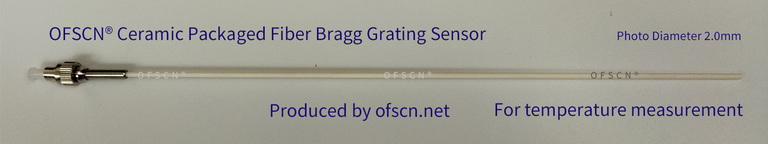

Ceramic Packaged Fiber Bragg Grating Temperature Sensor - Single/Multipoint FBG Thermometer - Insulating properties

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

Product Functions: Single/multipoint temperature detection under electrified state, temperature measurement; temperature compensation for strain and stress sensors.

Overview of OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensors:

By utilizing the temperature measurement characteristics of the FBG, this sensor can be inserted, clamped, surface-mounted, or adhesive-bonded to the measured structure for temperature detection and monitoring. It can be widely used in industrial production, power, railway, military, aerospace, and other fields for single-point or quasi-distributed temperature measurement.

|

|

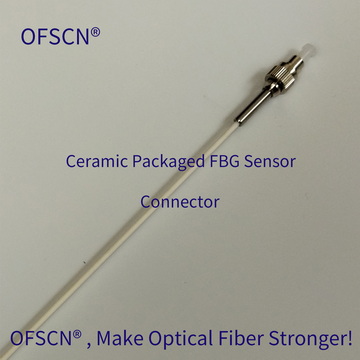

The OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensor can package both single-point and multipoint fiber bragg gratings (FBGs).

By selecting FBGs with different temperature resistance grades, the product can adapt to temperature environments ranging from -200°C to 800°C. In terms of principles and actual measurements, this FBG temperature sensor is a universal product and does not have compatibility issues with FBG demodulation equipment. When used with a matching FBG demodulator, the product can also be called an industrial-use capillary thermometer.

|

|

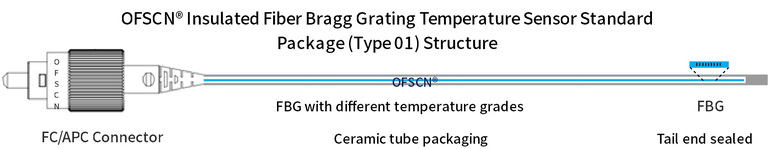

OFSCN® Insulated Single-Point Fiber Bragg Grating Temperature Sensor (ceramic packaging) |

|

|

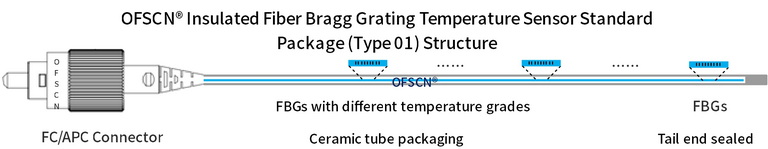

OFSCN® Insulated Multipoint (Array) Fiber Bragg Grating Temperature Sensor (ceramic packaging) |

Overall Parameters of OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensors:

|

Brand |

OFSCN® |

|

Product Name |

OFSCN® Insulated Fiber Bragg Grating Temperature Sensor (ceramic packaging) |

|

Product Model |

BNCG-SFBG-SH100-01-FC/APC-0.2M-JY (multiple models, provided as an example) |

|

Product Structure: Prefabricated fiber connectors + outer diameter 2.0/3.0 mm ceramic tube + single/multipoint fiber Bragg grating + sealed end |

|

※ Length Range |

10 cm to 1 m (specific length depends on inventory) |

Parameters of FBG used in OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensors:

|

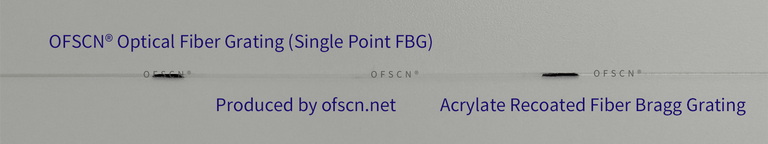

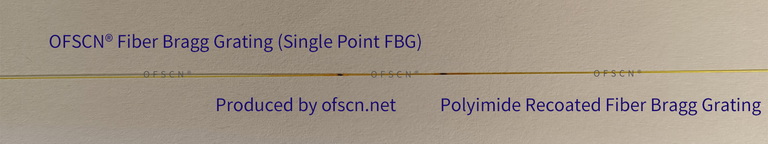

| Single-point fiber bragg grating (optional serial configuration) |

|

| Single-point fiber bragg grating (optional serial configuration) |

|

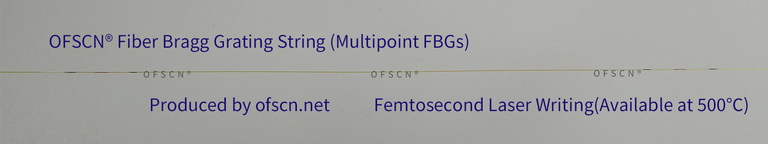

| Femtosecond laser-written fiber bragg grating array |

|

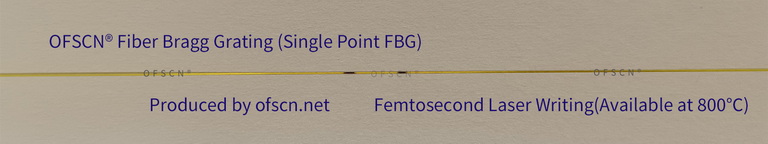

| Femtosecond laser-written fiber bragg grating |

Click here to view the parameters of the available FBG/FBG strings for OFSCN® Ceramic Packaged FBG temperature sensors:

Gold-Coated Fiber Bragg Grating - Gold-Plated FBG Array - Fbg in Metal Optical Fiber

Fiber connector specifications for the OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensors:

Note: Fiber connectors are made of metal and are not insulated!

|

|

Fiber connector types |

FC、ST、SC、LC |

|

|

Fiber connector endface types |

APC |

PC |

|

Fiber connector ferrule material |

Ceramic |

|

|

Fiber connector insertion loss |

<0.2db |

<0.2db |

|

Fiber connector return loss |

>-60db |

>-40db |

|

Fiber connector storage environment |

-40℃ to +85℃ |

|

|

Fiber connector operating environment: |

-40℃ to +75℃ |

|

|

※Fiber connector options |

FC/APC, FC/PC with optional high-temperature resistant connectors (material withstands temperatures up to 550°C, subject to availability) |

|

Click here to view the parameters of the available fiber connectors for OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensors:

120℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

200℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

300℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - APC

Insulation sheath and end of the OFSCN® Ceramic Packaged FBG Temperature Sensors:

|

|

Insulation sheath type |

OFSCN Ceramic Packaged Fiber Bragg Grating Temperature Sensor (Standard ceramic packaging) |

|

Sheath diameter |

2.0 / 3.0mm (or other options) |

|

Insulation sheath material |

Ceramic |

|

Insulation sheath thickness |

0.5 / 1.0mm (or other options) |

|

Weight of the FBG temperature sensor |

Calculated based on different structures |

|

Tensile strength |

Calculated based on different structures (relatively fragile) |

|

Lateral pressure resistance |

Calculated based on different structures (relatively fragile) |

|

Compressive strength |

Calculated based on different structures (relatively fragile) |

|

End packaging form of the FBG temperature sensor |

Sealed according to different temperature grades |

|

※Sheath and end options of the FBG temperature sensor |

Sensor diameter (2.0mm / 3.0mm), non-conventional corrosion-resistant solution |

Composition of OFSCN® Ceramic Packaged FBG Temperature Sensing System:

OFSCN® Ceramic Packaged Fiber Bragg Grating Temperature Sensing System consists of OFSCN® Fiber Bragg Grating Temperature Sensors, OFSCN® Fiber Optic Patch Cords and OFSCN® Fiber Bragg Grating Interrogators (Demodulators), which together constitute the Fiber Bragg Grating Temperature Monitoring System.

OFSCN Fiber Bragg Grating (Fiber Optic Grating) Temperature Sensor Overview Video:

Features of OFSCN® Ceramic-Packaged Fiber Bragg Grating Temperature Sensors:

- Broad Temperature Range: The sensor can operate in an extreme temperature range, from -200°C to +800°C, depending on the type of optical fiber used.

- High Performance: It offers high sensitivity, fast thermal response, and good accuracy.

- Durable and Robust: The ceramic packaging provides insulation, moisture resistance, corrosion resistance, and high-temperature durability. It contains no flammable materials.

- Compact and Lightweight: The small size and low weight make it versatile for various installation methods.

- Universal Compatibility: The sensor is a general-purpose product that is compatible with any standard Fiber Bragg Grating (FBG) interrogator.

- Installation Flexibility: It can be inserted, clamped, surface-mounted, or glued onto the target structure.

- FBG Technology: It utilizes the temperature-sensing properties of a Fiber Bragg Grating, written using either UV mask or femtosecond laser point-by-point methods.

Possible Application Scenarios and Industries of OFSCN® Ceramic-Packaged Fiber Bragg Grating Temperature Sensors:

The unique combination of durability, high-temperature resistance, and small size makes the OFSCN® sensor suitable for a wide range of applications.

Application Scenarios Examples of OFSCN® Ceramic-Packaged Fiber Bragg Grating Temperature Sensors:

- Power and Energy: Monitoring temperature within turbines, boilers, or other critical components where high temperatures and electromagnetic interference (EMI) are concerns. Detecting hotspots in high-voltage equipment to prevent failures. The sensor's immunity to EMI is a significant advantage here. Monitoring the internal temperature of large battery packs, especially in electric vehicles or energy storage systems, for thermal management and safety.

- Aircraft Structures: Monitoring temperature changes in aircraft wings, engines, and other components during flight. The sensor's lightweight and small form factor are ideal for this.

- Missile and Rocket Propulsion: Measuring high temperatures in engine nozzles and fuel systems.

- Spacecraft: Monitoring temperatures in extreme thermal environments, from the cold of space to the heat of re-entry.

- Industrial Manufacturing:Monitoring engine blocks, exhaust systems, and brake components. Measuring internal temperatures in high-heat processes. The sensor’s high-temperature resistance and corrosion resistance are key benefits. Monitoring temperature in corrosive or explosive environments. The sensor's intrinsic safety (no electrical current) is a major advantage.

- Structural Health Monitoring (SHM): Monitoring temperature in concrete structures, bridges, or tunnels to assess thermal expansion and contraction, which is a key factor in structural integrity.Railways: Monitoring temperatures of tracks, wheels, and braking systems to detect potential faults.

- Medical and Research:Precise temperature measurement in experimental setups, particularly those with strong magnetic fields (e.g., MRI machines) where conventional sensors fail due to EMI.

Industry Examples of FSCN® Ceramic-Packaged Fiber Bragg Grating Temperature Sensors:

- Industrial Production: For precise temperature control and monitoring in factories and plants.

- Electric Power: Monitoring transformers, cables, generators, and other critical power infrastructure.

- Railway: Temperature detection in tracks, train components, and signaling systems.

- Military: Applications requiring robust and reliable temperature sensing in demanding conditions.

- Aerospace: Monitoring temperatures in aircraft structures, engines, and space vehicles.

- Oil & Gas: Temperature sensing in pipelines, wells, and storage facilities.

- Chemical Industry: Monitoring temperatures in reactors, tanks, and pipelines where corrosive materials are present.

- Renewable Energy: Temperature monitoring in solar panels, wind turbine components, and geothermal systems.

- Research & Development: Used in laboratories for various temperature-sensitive experiments and tests.

DCYS is a professional manufacturer of insulated fiber grating temperature sensors (ceramic package), providing ceramic FBG temperature sensor principle, package design, working temperature range, advantages and disadvantages, installation and use, calibration experiment report, normal temperature breakdown voltage and other information; our insulated FBG temperature sensor's (ceramic package) brand is "OFSCN". Bulk purchase, better price!