Fiber Bragg Grating Displacement Sensor - FBG Displacement Meter - Crack Meter - FBG Displacement Sensing System

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

Product Function: High-precision, real-time measurement of relative displacement between objects or structures. Monitoring displacement of various cracks, potential landslides, and deformations.

Principle of Fiber Bragg Grating Displacement Sensor:

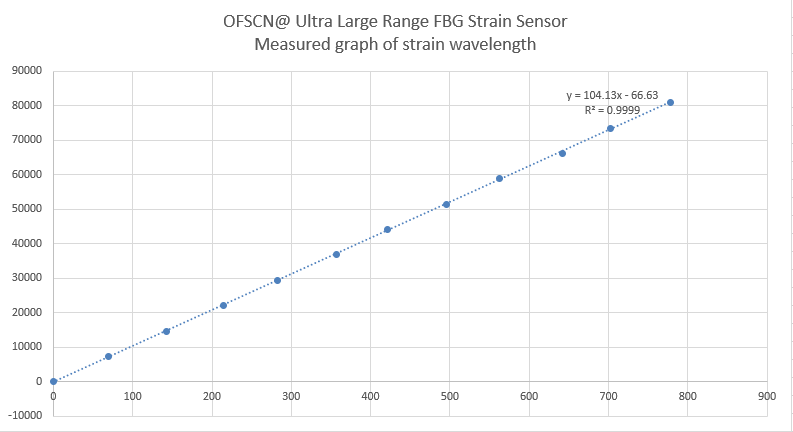

The OFSCN® FBG displacement sensor is a parameter extraction application of DCYS's FBG strain sensor. The relationship is given by Displacement = Total Length × Strain. Therefore, the structure of the FBG displacement sensor is the same as that of DCYS's FBG strain sensor, and its factory calibration formula corresponds length values to wavelengths.

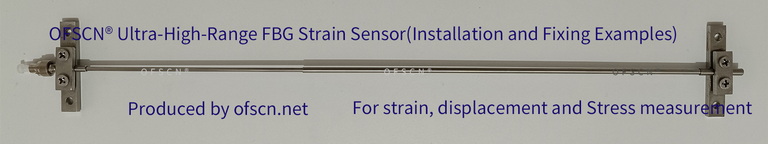

Fiber Bragg Grating Displacement Sensor Structure and Appearance:

OFSCN® Fiber Bragg Grating Displacement Sensor is OFSCN® Ultra-Large Range Fiber Bragg Grating Strain Sensor, which consists of a fiber optic connector, an all-metal stainless steel seamless steel pipe/elastic material, and a fiber Bragg grating (FBG) package.

Composition of Fiber Bragg Grating Displacement Sensing System:

OFSCN® Fiber Bragg Grating Displacement Sensing System consists of OFSCN® Fiber Bragg Grating Displacement Sensor, OFSCN® Sensor Mounting Fixture and OFSCN® Fiber Bragg Grating Demodulator, which together constitute the Fiber Bragg Grating Displacement Monitoring System.

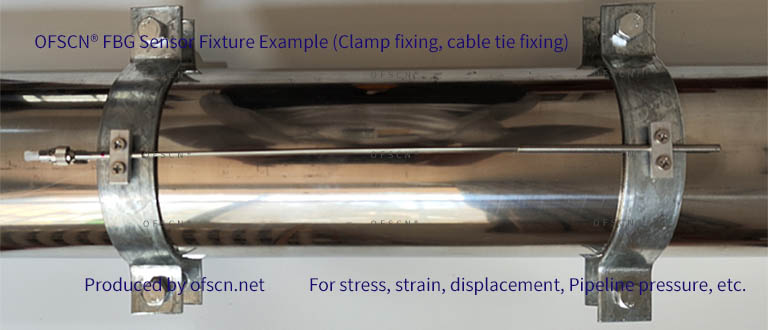

OFSCN® series fiber optic Bragg grating Displacement sensor fixture customization and installation example:

|

| OFSCN® Series FBG Strain Sensor Gluing and Surface Mounting Installation Examples (Customized Fixtures) |

|

| OFSCN® Series FBG Strain Sensor Bolt-Fixed and Welded Installation Examples (Customized Fixtures) |

|

| OFSCN® series FBG strain sensor pipe clamp installation example (customized clamp), pipe longitudinal measurement |

Common application industries of fiber grating displacement sensors (examples):

The unique advantages of OFSCN® fiber grating displacement sensors make them widely used in many key industries:

Civil engineering:

Bridge monitoring: measure the expansion joint displacement, main beam deflection, crack development, tower column deformation, cable stretching, etc. of the bridge to evaluate the structural health of the bridge.

Tunnel monitoring: monitor the convergence deformation, crack changes, and ground settlement of the tunnel lining.

Dam monitoring: measure the deformation, settlement, cracks, bedrock displacement, etc. of the dam.

High-rise buildings: monitor the settlement, tilt, structural vibration, interlayer displacement, and crack development of the building.

Foundation pits and slopes: monitor the surrounding displacement caused by foundation pit excavation, the slip and deformation of the slope, and warn of geological disasters.

Subway and underground engineering: monitor the deformation and settlement of underground structures.

Historical building and cultural relic protection: monitor the tiny deformation and cracks of ancient buildings so that protective measures can be taken in time.

Oil, natural gas and petrochemicals:

Pipeline monitoring: monitor the displacement caused by deformation, settlement, and corrosion of oil and gas pipelines to prevent leakage.

Offshore platform: monitor the structural deformation, stress and settlement of offshore drilling platforms.

Storage tank: monitor the deformation and settlement of large oil storage tanks.

Transportation:

Railway: monitor the deformation of rails, roadbed settlement and tunnel structural health.

Aerospace: monitor the strain and deformation of key components such as aircraft wings, fuselages and engines for structural health monitoring.

Energy field:

Nuclear power plant: monitor the deformation of the internal and surrounding structures of nuclear reactors due to its anti-radiation and anti-electromagnetic interference characteristics.

Wind power generation: monitor the vibration and deformation of wind turbine blades and towers.

Water conservancy projects:

Reservoir dams: Same as civil engineering, monitor the deformation, seepage, etc. of reservoir dams.

Geological disaster monitoring:

Landslide monitoring: real-time monitoring of the deep and surface displacement of landslide bodies and provide early warning.

Ground fissure monitoring: monitor the development and closure of surface fissures.

Mechanical manufacturing and intelligent equipment:

Large equipment monitoring: monitor the operating status of heavy machinery, industrial robots and other equipment, and the displacement caused by fatigue damage.

Material testing: measuring the strain and displacement of materials in material mechanics testing.

Mining:

Coal mines: monitoring the displacement of underground tunnel roof, surrounding rock deformation, support compression, etc. to improve mine safety.

Fiber Bragg Grating Displacement Sensor Range and Calibration (Take a sensor with a length of 30 cm as an example):

Advantages of Fiber Bragg Grating Displacement Sensor:

Due to its unique physical properties and working principle, OFSCN® fiber Bragg grating displacement sensor has a series of significant advantages over traditional electrical sensors:

Strong anti-electromagnetic interference ability:

The optical fiber used in OFSCN® fiber Bragg grating displacement sensor is a dielectric material, non-conductive, and completely unaffected by electromagnetic fields, radio frequency interference, lightning, high-voltage arcs, etc. This makes it very suitable for harsh environments such as high-voltage power transmission and transformation, lightning-prone areas, rail transportation, and industrial strong electromagnetic fields.

Traditional electrical sensors are easily interfered with in these environments, resulting in distorted measurement data or equipment damage.

Intrinsically safe and explosion-proof:

OFSCN® fiber Bragg grating displacement sensor is a passive device, not charged, and does not generate sparks or arcs. Therefore, it has higher safety in environments with flammable and explosive (such as oil, natural gas, chemical industry, coal mines) or toxic gases.

No complex explosion-proof treatment is required, which simplifies system design and installation.

Corrosion-resistant and resistant to harsh environments:

The optical fiber material (quartz glass) used in OFSCN® fiber Bragg grating displacement sensor has good chemical stability and is not easily corroded by chemical substances such as acid and alkali. Through appropriate packaging (such as stainless steel, engineering plastics, FRP, etc.), the sensor can work stably for a long time in corrosive environments such as humidity, underwater, acid rain, and salt spray.

Small size and light weight:

OFSCN® fiber Bragg grating displacement sensor has a very thin diameter, which is convenient for embedding into the structure or installing in a narrow space. Light weight and little impact on the measured structure, especially suitable for aerospace, composite materials and other fields.

After inheriting with fiber Bragg grating demodulator, multi-point monitoring can be achieved:

Utilizing the wavelength encoding characteristics of fiber Bragg grating, multiple FBG sensors with different center wavelengths can be measured simultaneously. It greatly simplifies wiring and reduces system complexity and cost.

Long transmission distance and low signal attenuation:

The optical signal of OFSCN® fiber Bragg grating displacement sensor has very low attenuation during transmission in optical fiber, which can achieve long-distance (tens of kilometers or even farther) signal transmission, facilitating centralized data collection and remote monitoring. This is very beneficial for monitoring large structures (such as bridges, pipelines, and dams).

High sensitivity and high precision:

The wavelength change of OFSCN® fiber Bragg grating displacement sensor is very sensitive to external strain changes, and can achieve micron-level displacement measurement accuracy.

Good repeatability, stable and reliable measurement results.

Good long-term stability:

The physical and chemical properties of the optical fiber material used in OFSCN® fiber Bragg grating displacement sensor are stable, and FBG itself has no moving parts and is not easy to age, ensuring the stability of the sensor in long-term monitoring.

Easy to integrate with the structure:

Beijing Dacheng Yongsheng Technology Co., Ltd. has developed a variety of installation fixtures for the application of OFSCN® fiber Bragg grating displacement sensor, so that it can be closely integrated with the measured structure through various methods such as pasting, embedding, welding, etc., and can even be pre-buried in new structures.

Good fatigue resistance:

The material of OFSCN® fiber Bragg grating displacement sensor has good fatigue resistance when subjected to periodic loads, and is suitable for long-term dynamic monitoring.

Can be used for structural health monitoring:

All the above advantages make OFSCN® Fiber Bragg Grating Displacement Sensor one of the core technologies in the field of structural health monitoring, which can provide real-time and accurate structural deformation data for evaluating structural safety and predicting potential failures.

OFSCN® Fiber Bragg Grating Displacement Sensor Video Display:

DCYS is a professional fiber grating displacement sensing system manufacturer, providing FBG displacement meter principle, packaging design scheme, application information in dams, mine collapses, roadbed settlements, landslides, crane booms and other fields; Our FBG displacement sensor‘s brand is "OFSCN". Bulk purchase, better price!