300°C Fiber Bragg Grating Temperature Sensor - Single-Point/Multipoint FBG Thermometer - FBG Temperature Sensors

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

Product Alias: OFSCN 300℃ FBG Temperature Sensor, High-Temperature Fiber Optic Sensor, Industrial FBG Thermometer, Seamless Stainless Steel FBG Sensor, Polyimide Fiber Temperature Sensor, Quasi-Distributed Temperature Sensor, Single-Point FBG Temperature Probe, Fiber Optic Grating Sensor, Temperature Monitoring FBG, Corrosion-Resistant FBG Sensor.

Product Functions and Uses: Single-point/multipoint temperature detection and measurement in the range of -200°C to 300°C; temperature compensation for strain and stress sensors; Precision Temperature Monitoring; Environmental Monitoring Solutions; Digital Temperature Gauge; Accurate Temperature Measurement; Temperature Sensing Devices; Climate Control Sensors; Industrial Temperature Sensors; IoT Temperature Monitoring; Smart Temperature Probes; High-Accuracy Thermometers; Remote Temperature Monitoring; Temperature Data Collection Devices

Video Explanation of the OFSCN® 300℃ Fiber Bragg Grating Temperature Sensors :

Product Overview of the OFSCN® 300℃ Fiber Bragg Grating Temperature Sensors:

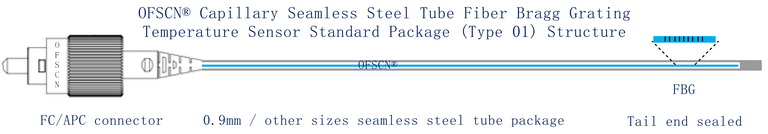

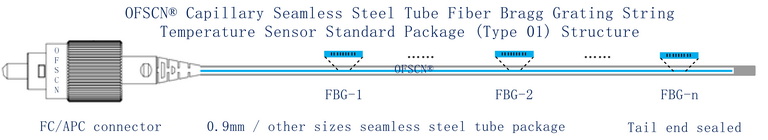

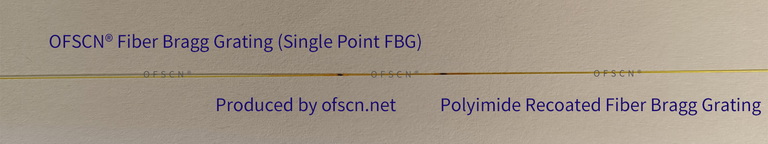

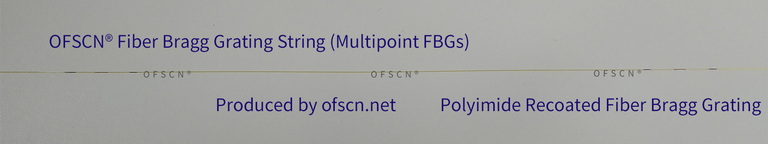

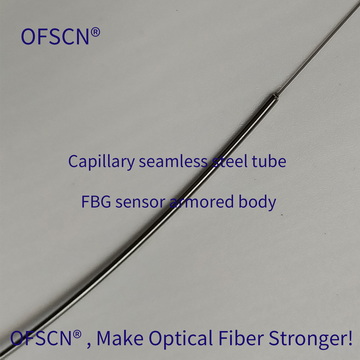

OFSCN® 300℃ Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensor consists of fiber connectors (FC, SC, LC, ST, etc.), stainless steel seamless tube, and single-point/serial fiber Bragg grating (FBG) encapsulation. The FBG is written using the ultraviolet light masking method, and the fiber used is polyimide-coated fiber.

It is a FBG sensor with high sensitivity, fast heat conduction, good accuracy, small size, light weight, high tensile and compressive strength, high temperature resistance, waterproof and moisture-proof properties, non-combustible, and corrosion resistance.

By utilizing the temperature sensing characteristics of the Bragg fiber grating (FBG), this sensor can be inserted, clamped, adhered, or embedded into the structure to be tested for temperature detection and monitoring. It can be widely used in various industries such as industrial production, chemical industry, power, railway, military, aerospace, for single-point or quasi-distributed temperature measurement.

|

OFSCN® 300℃ Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensor can be encapsulated with a single-point FBG or a serial FBG string/array.

This product is currently defined as a 300℃ product, encapsulating a FBG fabricated using the ultraviolet light masking method, with a polyimide coating that allows long-term use in a 300℃ environment (can be repeatedly used at 370℃).

In terms of principle and actual measurement, this FBG temperature sensor is a universal product and does not have compatibility issues with FBG demodulation equipment. When used with a matching FBG demodulator, this product can also be referred to as an industrial capillary thermometer.

|

| OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensor (Single-point) |

|

| OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensor (FBG string/array inside) |

Overall Parameters of the OFSCN® 300℃ Fiber Bragg Grating Temperature Sensors:

|

Brand |

OFSCN® |

|

Fiber Bragg Grating Temperature Sensor Name |

OFSCN® 300°C Fiber Bragg Grating Temperature Sensor |

|

Fiber Bragg Grating Temperature Sensor Model |

BNCG-SFBG-PI300-01-FC/APC-2M (multiple models available, example only) |

|

Product Structure: Prefabricated fiber optic connectors + 0.9mm stainless seamless steel tube + single-point/multipoint fiber Bragg grating + end welding |

|

※Length Range |

10 centimeters to several meters (specific length depends on stock availability) |

Parameters of the Fiber Bragg Grating (FBG) used in the OFSCN® 300℃ Fiber Bragg Grating Temperature Sensors:

|

| Single-point Fiber Bragg Grating |

|

| Multipoint Fiber Bragg Grating String/Array |

Click here to view the parameters of the available FBG/FBG strings for OFSCN® 300℃ FBG temperature sensors:

Fiber Optic Connector Specifications for OFSCN® 300℃ FBG Temperature Sensors:

|

|

|

Fiber connector types for FBG temperature sensor |

FC/APC、FC/PC、SC、LC、ST |

|

|

Fiber connector end face types |

APC |

PC |

|

Fiber connector insert material |

Ceramic |

|

|

Fiber connector insertion loss |

<0.2db |

<0.2db |

|

Fiber connector return loss |

>-60db |

>-40db |

| Fiber connector storage environment |

-40℃ to +85℃ |

|

|

Fiber connector operating environment |

-40℃ to +75℃ |

|

| ※ Additional options for fiber connector |

FC/APC, FC/PC optional high-temperature resistant connectors, high-temperature resistant connector materials can withstand up to 550℃ (depending on stock availability) |

|

Click here to view the parameters of the available fiber connectors for OFSCN® 300℃ Fiber Bragg Grating Temperature Sensors:

120℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

200℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

300℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - APC

Armor and Tail End of the OFSCN® 300℃ Fiber Bragg Grating Temperature Sensors:

|

|

| Armor type for FBG temperature sensor |

OFSCN® Capillary Seamless Steel Tube Fiber/Fiber Bragg Grating Sensor Standard Packaging (Type 01) |

|

Armor diameter for FBG temperature sensor |

0.9mm |

|

Material of Seamless Steel Tube Used in the Fiber Bragg Grating Temperature Sensor |

316L Stainless Steel |

|

Wall Thickness of Seamless Steel Tube Used in the Fiber Bragg Grating Temperature Sensor |

0.18mm |

|

Weight of Seamless Steel Tube Used in the Fiber Bragg Grating Temperature Sensor |

Approximately 3.2g/m (excluding connectors) |

|

Tensile Strength of the Fiber Bragg Grating Temperature Sensor |

>400N (excluding connectors) |

|

Lateral Pressure Resistance of the Fiber Bragg Grating Temperature Sensor |

>9000N (excluding connectors) |

|

Compressive Strength of the Fiber Bragg Grating Temperature Sensor |

>180Mp (excluding connectors) |

|

Tail End Packaging Form of the Fiber Bragg Grating Temperature Sensor |

Brazing |

|

※ Optional Armor and Tail End of the Fiber Bragg Grating Temperature Sensor |

Armor Diameter (0.9mm/2.0mm/3.0mm), unconventional corrosion-resistant solutions |

Composition of OFSCN® 300℃ Fiber Bragg Grating Temperature Sensing System:

OFSCN® 300℃ Fiber Bragg Grating Temperature Sensing System consists of OFSCN® Fiber Bragg Grating Temperature Sensors, OFSCN® Fiber Optic Patch Cords and OFSCN® Fiber Bragg Grating Interrogators (Demodulators), which together constitute the Fiber Bragg Grating Temperature Monitoring System.

Features of OFSCN® 300℃ Fiber Bragg Grating Temperature Sensor:

- High Temperature Resistance: The sensor utilizes a polyimide-coated optical fiber, allowing for long-term use in temperatures up to 300℃ and intermittent use up to 370℃.

- Durable Construction: It features a 0.9mm seamless stainless steel tube housing, providing excellent protection. The sensor tip is sealed by welding.

- Precise Measurement: Based on the principle of Fiber Bragg Grating (FBG), it offers high sensitivity, fast thermal response, and excellent accuracy.

- Compact and Lightweight: Its small size and light weight make it easy to install in various configurations.

- Robustness: The sensor boasts high tensile strength, high compressive strength, waterproof and moisture-proof properties, and corrosion resistance. It contains no flammable materials.

- Universal Compatibility: It is a general-purpose product that is compatible with various FBG interrogators, effectively functioning as an industrial thermometer when paired with one.

- Flexible Installation: It can be embedded, clamped, surface-mounted, glued, or buried within structures for temperature detection and monitoring.

Possible Application Scenarios and Industries of OFSCN® 300℃ Fiber Bragg Grating Temperature Sensor:

Given its robust design and high-temperature capabilities, the OFSCN® 300℃ Fiber Bragg Grating Temperature Sensor is suitable for a wide range of applications across various industries.

This sensor is particularly well-suited for any application requiring single-point or quasi-distributed temperature measurement where traditional sensors may fail due to high temperatures, electromagnetic interference, or harsh environmental conditions.

Application Scenarios Examples of OFSCN® 300℃ Fiber Bragg Grating Temperature Sensor:

- Industrial Production:Real-time temperature monitoring in manufacturing processes, such as in ovens, furnaces, or extruders. Assessing the operating temperature of critical machinery to prevent overheating and ensure optimal performance. Monitoring temperature profiles during the curing of composites, adhesives, or coatings.

- Chemical Industry: Precise temperature measurement within chemical reactors to optimize reactions and ensure safety. Detecting temperature fluctuations in pipelines transporting hot chemicals or fluids. Monitoring temperatures in storage tanks for various chemical substances.

- Power Industry: Temperature sensing within power transformers to detect hot spots and prevent failures. Monitoring the temperature of critical components in power generators. Temperature assessment of switchgear and other high-voltage components.

- Railway Industry: Detecting temperature changes in railway tracks, especially in areas prone to buckling or stress. Monitoring the temperature of braking components in trains. Temperature sensing in train engines and other critical mechanical parts.

- Military Industry: emperature monitoring in various military equipment and weapon systems operating under extreme conditions. ensing temperatures in engines and propulsion units. Monitoring temperature-induced stress in critical military structures.

- Aerospace Industry: Real-time temperature measurement in aircraft engines, exhaust systems, and other hot zones. Monitoring temperature during the manufacturing and in-flight operation of advanced composite materials. Sensing surface temperatures of aircraft and spacecraft due to aerodynamic friction. Monitoring fuel temperature in tanks and lines.

Industry Examples of OFSCN® 300℃ Fiber Bragg Grating Temperature Sensor:

- Industrial Production: For precise temperature control and monitoring in factories and plants.

- Electric Power: Monitoring transformers, cables, generators, and other critical power infrastructure.

- Railway: Temperature detection in tracks, train components, and signaling systems.

- Military: Applications requiring robust and reliable temperature sensing in demanding conditions.

- Aerospace: Monitoring temperatures in aircraft structures, engines, and space vehicles.

- Oil & Gas: Temperature sensing in pipelines, wells, and storage facilities.

- Chemical Industry: Monitoring temperatures in reactors, tanks, and pipelines where corrosive materials are present.

- Renewable Energy: Temperature monitoring in solar panels, wind turbine components, and geothermal systems.

- Research & Development: Used in laboratories for various temperature-sensitive experiments and tests.

DCYS is a professional manufacturer of 300°C FBG temperature sensor, providing information on the principle, package design, working temperature range, advantages and disadvantages, installation and usage, and calibration experiment reports of 300°C FBG temperature sensors; The 300°C FBG temperature sensor brand is "OFSCN". Bulk purchase, better price!