500°C Femtosecond Fiber Bragg Grating Temperature Sensor - Single-Point/Multipoint FBG Thermometer - FBG Temperature Sensors

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

Product Alias: Fiber Optic Temperature Sensor,FBG Temperature Sensor,Fiber Bragg Grating Sensor,High Temperature Fiber Optic Sensor,500℃ FBG Sensor,Industrial Fiber Optic Thermometer,Stainless Steel FBG Sensor,Femtosecond FBG Sensor,Distributed Temperature Sensor,Quasi-Distributed Temperature Sensor,Polyimide Fiber Sensor,Corrosion Resistant Temperature Sensor.

Product Function: Single-point/multipoint temperature detection and measurement in the range of -200°C to 600°C; Precision Temperature Monitoring; Environmental Monitoring Solutions; Digital Temperature Gauge; Accurate Temperature Measurement; Temperature Sensing Devices; Climate Control Sensors; Industrial Temperature Sensors; IoT Temperature Monitoring; Smart Temperature Probes; High-Accuracy Thermometers; Remote Temperature Monitoring; Temperature Data Collection Devices

Video Explanation of OFSCN® 500℃ FBG Temperature Sensors:

Product Overview of OFSCN® 500℃ FBG Temperature Sensors:

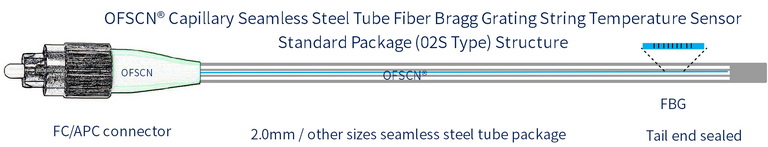

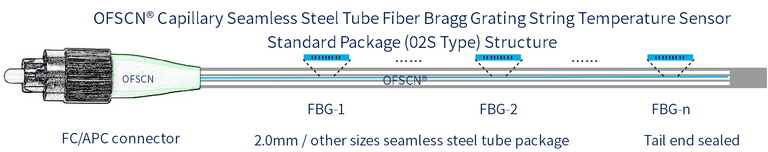

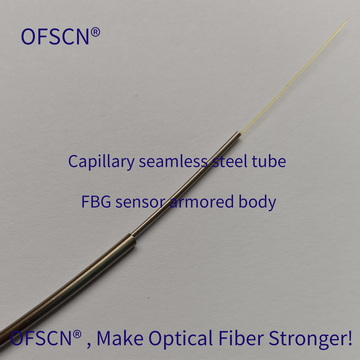

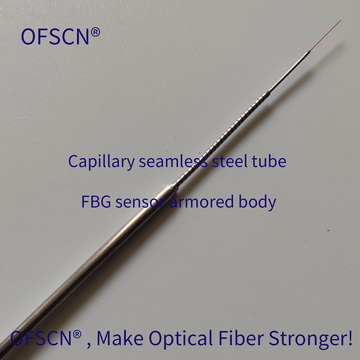

OFSCN® 500°C capillary seamless steel tube FBG temperature sensor consists of fiber connectors (FC, SC, LC, ST, etc.), stainless steel seamless tube, and single-point/serial femtosecond FBG encapsulation. The FBG is written using femtosecond laser point-by-point inscription technique, and the fiber used is doped polyimide fiber.

It is a FBG sensor with high sensitivity, fast thermal conduction, good accuracy, small size, light weight, high tensile strength, high compressive strength, high temperature resistance, waterproof and moisture-proof, non-combustible, and corrosion resistance.

By utilizing the temperature measurement characteristics of the FBG, this sensor can be inserted, clamped, attached, glued, or embedded into the measured structure for temperature detection and monitoring. It can be widely used in industrial production, power, railway, military, aerospace, and other fields for single-point or quasi-distributed temperature measurement.

|

| Recommended structure 01 |

|

| Recommended structure 02 |

OFSCN® 500 degrees Celsius capillary seamless steel tube FBG temperature sensor can be encapsulated with a single-point femtosecond FBG or a multi-point femtosecond FBG string/array.

This product is currently defined as 500 degrees Celsius, which is related to the fiber quality and FBG quality. The product is encapsulated with femtosecond FBG and can be used for long-term applications in a 550 degrees Celsius environment (recommended temperature range from -200 degrees Celsius to 500 degrees Celsius, and it can be used repeatedly at higher temperatures, but temperatures above 600 degrees Celsius are not recommended, and the required product temperature should be specified when placing an order).

In terms of principle and actual measurements, this FBG temperature sensor is a universal product, and there is no issue with the compatibility of FBG demodulation equipment. With the matching FBG demodulator, this product can also be called an industrial-capillary thermometer.

|

|

OFSCN® Capillary Seamless Steel Tube Femtosecond Fiber Bragg Grating Temperature Sensor(Single-Point) |

|

| OFSCN® Capillary Seamless Steel Tube Femtosecond Fiber Bragg Grating Temperature Sensor (FBG String/Array inside) |

General Overview of OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

|

FBG Temperature Sensor Brand |

OFSCN® |

|

FBG Temperature Sensor Product Name |

OFSCN® 500 ℃ Fiber Bragg Grating temperature sensor |

|

FBG Temperature Sensor Product Model |

BNCG-SFBG-ZD500-02S-FC/APC-5M (various models available, this is just an example) |

|

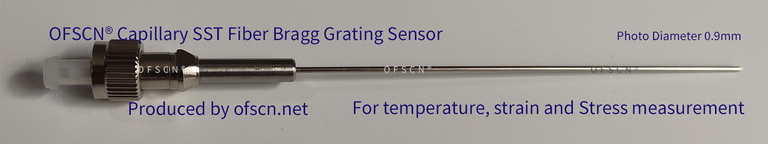

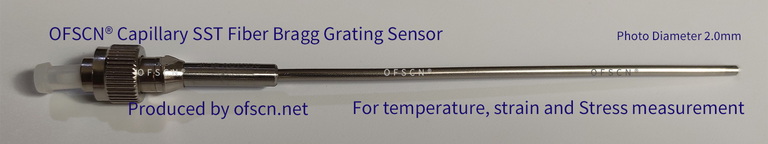

Product Structure: Prefabricated fiber connector + 0.9mm/2.0mm stainless steel seamless tube + stainless steel strip + stainless steel seamless tube + single-point/multipoint femtosecond fiber Bragg grating + end welding |

|

※ Length Range |

From 10 centimeters to several meters (specific length depends on inventory) |

Parameters of the FBG used in the OFSCN® 500℃ FBG Temperature Sensors:

|

|

|

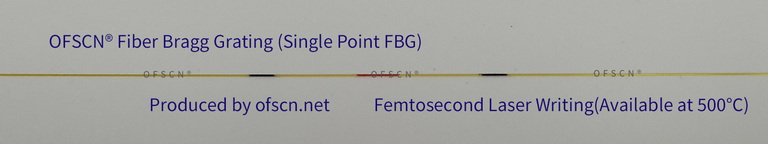

Single-point Femtosecond Fiber Bragg Grating |

|

|

|

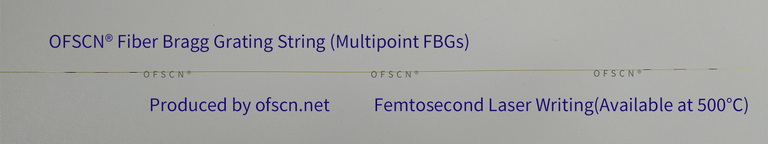

| Multipoint Femtosecond Fiber Bragg Grating String/Array |

Click here to view the parameters of the available FBG/FBG strings for OFSCN® 500℃ FBG temperature sensors:

Specifications of Fiber Connectors used in the OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

|

|

|

Fiber Connector Type for the FBG Temperature Sensor |

FC/APC、FC/PC、SC、LC、ST |

|

|

Fiber Connector End Face Type |

APC |

PC |

|

Fiber Connector Insertion Core Material |

Ceramic |

|

|

Fiber Connector Insertion Loss |

<0.2db |

<0.2db |

|

Fiber Connector Return Loss |

>-60db |

>-40db |

|

Fiber Connector Storage Environment |

-60℃ to +180℃ |

|

|

Fiber Connector Operating Environment |

-60℃ to +180℃ |

|

|

※ Optional Fiber Connector |

FC/APC, FC/PC with high-temperature resistant connectors, the connector can withstand temperatures of up to 300 degrees Celsius (depends on inventory) |

|

Click here to view the parameters of the available fiber connectors for OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

120℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

200℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - PC/APC

300℃ Fiber Optic Connector - High Temperature Optical Fiber Connector - FC/ST/SMA - APC

Armor and Tail End of the OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

|

|

|

|

|

Type of Armor for the FBG Temperature Sensor |

OFSCN® Capillary Seamless Steel Tube Fiber/Fiber Bragg Grating Sensor Standard Packaging ( 02S Type ) |

|

Armor Diameter of the FBG Temperature Sensor |

2.0mm |

|

Stainless Steel Material used for the Fiber Bragg Grating Temperature Sensor |

316L Stainless Steel + Stainless Steel Strip(Optional) + 316L Stainless Steel (Two/Three-layer structure) |

|

Wall Thickness of the Seamless Steel Tube used for the Fiber Bragg Grating Temperature Sensor |

0.2mm+0.2mm(Optional)+0.15mm (Two/Three-layer structure) |

|

Weight of the Seamless Steel Tube used for the Fiber Bragg Grating Temperature Sensor |

Approximately 13 g/m (excluding connectors) |

|

Tensile Strength of the Fiber Bragg Grating Temperature Sensor |

>1600N (excluding connectors) |

|

Lateral Pressure Resistance of the Fiber Bragg Grating Temperature Sensor |

>9000N (excluding connectors) |

|

Compressive Strength of the Fiber Bragg Grating Temperature Sensor |

>180Mp (excluding connectors) |

|

Tail End Encapsulation Form of the Fiber Bragg Grating Temperature Sensor |

High-temperature welding |

|

Welding Material of the Fiber Bragg Grating Temperature Sensor |

316L Stainless Steel (same as the armor material) |

|

※ Armor and Tail End options of the Fiber Bragg Grating Temperature Sensor: |

Sensor Diameter (0.9mm/2.0mm/3.0mm), unconventional corrosion-resistant solutions |

Composition of OFSCN® 500℃ Fiber Bragg Grating Temperature Sensing System:

OFSCN® 500℃ Fiber Bragg Grating Temperature Sensing System consists of OFSCN® Fiber Bragg Grating Temperature Sensors, OFSCN® Fiber Optic Patch Cords and OFSCN® Fiber Bragg Grating Interrogators (Demodulators), which together constitute the Fiber Bragg Grating Temperature Monitoring System.

Features of OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

- High Sensitivity: It can detect even subtle temperature changes accurately.

- Fast Thermal Conduction: The sensor quickly responds to temperature fluctuations in its environment.

- Excellent Accuracy: Provides precise and reliable temperature readings.

- Compact and Lightweight: Its small size and light weight make it easy to integrate into various structures.

- High Tensile and Compression Resistance: The sensor's robust construction ensures durability under significant mechanical stress.

- High Temperature Resistance: Encapsulating a femtosecond FBG, it can be used long-term in environments up to 500°C (recommended range: -200°C to 500°C). It can withstand repeated exposure to higher temperatures, though continuous use above 600°C is not advised.

- Waterproof and Moisture-proof: Designed to perform reliably in wet or humid conditions.

- Non-flammable Materials: Contains no combustible components, enhancing safety.

- Corrosion Resistance: Built to withstand corrosive environments.

- Femtosecond Laser Engraved FBG: The grating is precisely inscribed using femtosecond laser point-by-point technology on doped polyimide fiber.

- Robust Construction: Features a fiber optic connector (commonly FC/APC) at one end, with the FBG encapsulated within three layers of 0.9mm/2.0mm seamless stainless steel tubing, and a welded tail end.

- Universal Compatibility: Based on its principle and practical testing, this sensor is a general-purpose product and is compatible with all FBG interrogators. When paired with an FBG interrogator, it can function as an industrial thermometer.

Possible Application Scenarios and Industries of OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

Leveraging the temperature sensing properties of Fiber Bragg Gratings, this sensor can be inserted, clamped, surface-mounted, glued, or embedded into structures for temperature detection and monitoring. Its versatility makes it suitable for a wide range of single-point or quasi-distributed temperature measurement applications across various industries. This sensor's robust design and high-temperature capability make it an ideal choice for challenging environments where traditional electrical sensors might fail or pose safety risks.

Application Scenarios Examples of OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

- Industrial Production:Process monitoring in high-temperature environments.Temperature control in manufacturing lines.Monitoring of industrial furnaces, kilns, and ovens.

- Power Industry:Temperature monitoring of power cables, transformers, and switchgear.Status monitoring of power generation equipment.Safety monitoring in nuclear power plants.

- Railway Systems:Temperature monitoring of railway tracks to detect buckling or stress.Bearing temperature monitoring in trains.Structural health monitoring of bridges and tunnels.

- Military Applications:Temperature sensing in critical military equipment and systems.Structural integrity monitoring of defense installations.

- Aerospace Industry:Temperature monitoring of aircraft components, engines, and structures.Health monitoring of spacecraft and satellites.Composite material curing process monitoring.

- Civil Engineering:Structural health monitoring of bridges, tunnels, dams, and buildings.Temperature monitoring in concrete curing processes.

- Oil and Gas:Downhole temperature monitoring in wells.Pipeline integrity monitoring.Storage tank temperature monitoring.

- Research and Developmen

- t:Laboratory experiments requiring precise temperature measurements in harsh environments.

Industry Examples of OFSCN® 500℃ Fiber Bragg Grating Temperature Sensors:

- Industrial Production: For precise temperature control and monitoring in factories and plants.

- Electric Power: Monitoring transformers, cables, generators, and other critical power infrastructure.

- Railway: Temperature detection in tracks, train components, and signaling systems.

- Military: Applications requiring robust and reliable temperature sensing in demanding conditions.

- Aeros

- ace: Monitoring temperatures in aircraft structures, engines, and space vehicles.

- Oil & Gas: Temperature sensing in pipelines, wells, and storage facilities.

- Chemical Industry: Monitoring temperatures in reactors, tanks, and pipelines where corrosive materials are present.

- Renewable Energy: Temperature monitoring in solar panels, wind turbine components, and geothermal systems.

- Research & Development: Used in laboratories for various temperature-sensitive experiments and tests.

DCYS is a professional manufacturer of 500℃ FBG temperature sensors, providing information on the principle of 500℃ femtosecond FBG temperature sensors, packaging design solutions, operating temperature ranges, advantages and disadvantages, installation and usage, and calibration test reports; The FBG temperature sensor brand is "OFSCN". Bulk purchase, better price!