Fiber Bragg Grating 3D Force Sensor - Solid Surface Pressure Sensor - Pen-Style Force Sensor - Medical Needle Insertion Force Sensor

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

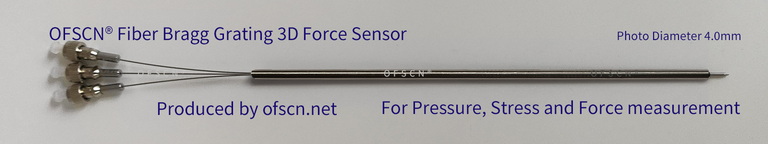

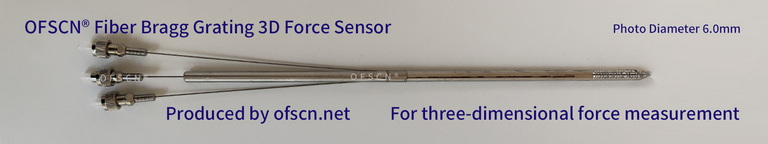

The product is a FBG 3D Force Sensor encapsulated in a seamless steel tube, also known as: FBG stress sensor, pen-style force sensor, pen-type dynamometer, fiber Bragg grating force pen, Solid surface pressure sensor, Fiber Bragg Grating 3-Axis Load Cell, Pen-style FBG Sensor, Fiber Optic Force Transducer, FBG Multi-axis Sensor, Hard Alloy Force Sensor.

Product function: Handheld measurement of small changes in pressure, stress, and pressure on solid surfaces, leather and other materials. This product is a custom product and can be tailored to order.

1. Product Overview of OFSCN® Fiber Bragg Grating 3D Force Sensor

The OFSCN® Fiber Bragg Grating (FBG) 3D Force Sensor is a high-precision, multi-axis force measurement product utilizing FBG sensing technology. The sensor adopts a compact and reliable pen-style structural design, capable of real-time, high-precision, and decoupled measurement of three-dimensional forces (Fx, Fy, Fz) applied to the sensing unit.

Its unique sensing structure, combined with a hard alloy rod as the base material, ensures high sensitivity and long-term stability of the sensing element. The seamless steel tube outer casing provides robust mechanical protection, making it suitable for various applications requiring precise force measurement or operation in electromagnetic interference environments, such as medical surgical robotics, precision assembly, and haptic feedback systems.

It can be widely used in the force measurement of industrial equipment, solid materials, metals, leather goods, and other fields.

2. Structure and Working Principle of OFSCN® Fiber Bragg Grating 3D Force Sensor

2.1 Structural Description

- Overall Structure: The sensor features a pen-style design, with a default length of 15 CM.

- External Protection: The outer casing is a seamless steel tube with a diameter of 4 mm / 6 mm, primarily used for user gripping and providing reliable mechanical and environmental protection for the internal core sensing unit.

- Sensing Unit: The core sensing unit uses a hard alloy rod as the base material, ensuring high rigidity and low creep characteristics.

- Fiber Configuration: 3 Fiber Bragg Gratings are uniformly arranged longitudinally along the circumference of the base material, spaced 120 degrees apart.

- Measurement Section: Each of the 3 FBGs is equipped with one force measurement section designed to sense the strain generated in the base material due to applied force.

- Pigtail Lead-out and Connector: The pigtails of the 3 FBGs are encapsulated and led out using seamless steel tubing to ensure the fibers are protected from lateral stress. The termination connector type is FC/APC.

2.2 Working Principle

When a three-dimensional force acts on the sensor tip, the hard alloy base material generates a complex strain field in the Fx, Fy, Fz directions. Due to the independent position and orientation of the 3 FBGs (120 separation), they each experience different axial strains, leading to unique wavelength shifts in their respective Bragg wavelengths (λ1, λ2, λ3).

By reading the 3 wavelength shifts using an FBG interrogator and applying the factory-provided calibration matrix relating the three-direction force to wavelength, precise, decoupled calculation of the Fx, Fy, Fz force components acting on the sensor can be achieved.

3. Key Technical Specifications of OFSCN® Fiber Bragg Grating 3D Force Sensor

|

Parameter |

Specification |

Notes |

|

Product Brand |

OFSCN® |

|

|

Product Name |

FBG 3D Force Sensor |

(Fiber Bragg Grating 3-Axis Force Sensor) |

|

Structure Type |

Pen-style |

Compact Design |

|

Outer Diameter |

4 mm / 6 mm |

Customizable |

|

Default Length |

15 CM |

Other customizable lengths available upon request |

|

Sensing Base Material |

Hard Alloy Rod |

High Rigidity, High Stability |

|

FBG Count |

3 Fibers |

120 circ Longitudinal Arrangement around the circumference |

|

Measurement Axes |

3D Force (Fx, Fy, Fz) |

Factory-provided 3-Direction Force vs. Wavelength Calibration |

|

Pigtail Encapsulation |

Seamless Steel Tube Encapsulation Lead-out |

Independent encapsulation for enhanced reliability |

|

Connector Type |

FC/APC |

Standard Fiber Optic Connector |

|

Operating Temp. |

-20℃ - 50℃ |

Higher temperatures require custom order (Contact us for details) |

|

Storage Temp. |

-40℃ - 75℃ |

Note: The parameters listed in this specification sheet are for the default configuration and can be adjusted and customized according to the user's specific application requirements.

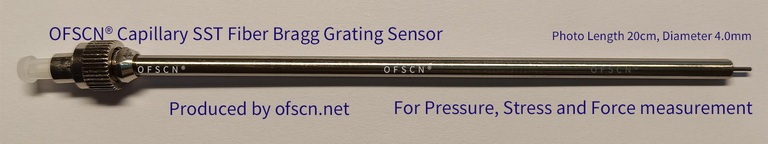

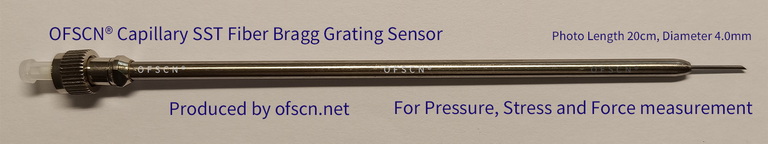

4. Other structural examples:

DCYS is a professional fiber grating solid surface pressure sensor manufacturer, providing fiber grating solid surface pressure sensor principles, patented structural design solutions, working accuracy, installation and use, temperature compensation, calibration experiment reports and other information; The brand of solid surface pressure sensor is "OFSCN". Buy in bulk and get better prices!

Looks good, can it be used to puncture biological tissues, such as animal skin?

You got it. The puncture of biological tissue is one of the application directions of this sensor in the biological and medical fields.

In addition, we are also looking for other application directions of this sensor.