Application of Fiber Bragg Grating Sensing Technology - Application of FBG Sensor - Application of FBG-Application of FBG Demodulator - Application of FBG Sensing in Industry

FBG Sensing Technology for Monitoring Angle, Curvature and Shape Sensing of Robots

Robotics is an emerging field that has revolutionized the manufacturing and automation industry. The use of robots in various industrial and non-industrial applications has increased over the years. As robots are becoming more complex and versatile, the demand for accurate shape sensing monitoring of robots is increasing. In this article, we will discuss the problems that fiber grating sensing technology can solve, and how Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS ) can help to monitor the shape sensing of robots in the robotics.

Fiber Bragg Grating Sensing Principle:

Fiber Bragg gratings (FBGs) are periodic structures that are inscribed in the core of an optical fiber. These structures reflect a specific wavelength of light that is determined by the periodicity of the grating. When the grating is subjected to mechanical or thermal strain, the reflected wavelength changes in a predictable manner. By monitoring the reflected wavelength, changes in strain, temperature, and other parameters can be detected. FBG sensors can be used to monitor a wide range of parameters, including strain, stress, temperature, and vibration.

Click the link below for more details:

Requirements Analysis for Shape Sensing Monitoring of Robots:

The shape sensing monitoring of robots requires the measurement of various parameters such as strain, temperature, and shape. Accurate shape sensing is critical for the control and navigation of robots. The sensors used for shape sensing must be small, lightweight, and durable to withstand the harsh operating conditions of robots. The sensors must also be capable of measuring small changes in shape with high accuracy.

Why Shape Sensing Monitoring for Robots is Needed:

The accurate measurement of robot shape is essential for many robotic applications, such as automated inspection, assembly, and manipulation. The shape of a robot can change due to external forces, temperature variations, or material degradation. By monitoring the shape of the robot, it is possible to ensure that the robot is performing as expected, and any anomalies can be detected and corrected before they cause significant problems.

Difficulties in Shape Sensing Monitoring of Robots:

The shape sensing monitoring of robots is challenging due to the complex and dynamic nature of robots. Robots are subject to various external forces, temperature changes, and material deformation. Additionally, the sensors used for shape sensing must be small, lightweight, and durable to withstand the harsh operating conditions of robots. The sensors must also be capable of measuring small changes in shape with high accuracy, which is challenging in the dynamic environment of robots.

What Problems can be Solved by FBG Sensing Technology:

Fiber grating sensing technology provides a reliable and accurate solution for shape sensing monitoring of robots. FBG sensors are small, lightweight, and durable, making them suitable for use in robots. They can measure changes in shape with high accuracy, providing precise shape sensing monitoring of robots. FBG sensors can also measure temperature and strain, which are critical parameters for the accurate measurement of robot shape.

Recommended Fiber Bragg Grating Angle, Shape, Curvature Sensors:

1. Product Overview

The OFSCN® Fiber Optic Grating Shape Sensor is a new generation of high-precision flexible sensor developed based on Distributed Fiber Bragg Grating (FBG) technology. It is specifically designed for the real-time perception and reconstruction of three-dimensional shapes. The product has been upgraded to its Third Generation, featuring a compact structure, high precision, strong immunity to electromagnetic interference, and robust adaptability to harsh environments. It is widely used in fields such as medical device navigation, industrial structural health monitoring, robotics, and aerospace.

Fiber Bragg Grating (FBG) Angular Sensor-Two-Dimensional Bending MeasurementPrinciple of Fiber Bragg Grating Angle Sensor:

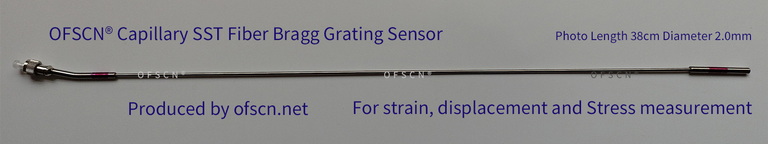

OFSCN® seamless steel pipe fiber Bragg grating angle sensor is a customized application of Dacheng Yongsheng fiber Bragg grating strain sensor. By utilizing the impact of the bending angle on the wavelength of the fiber Bragg grating, the angle change and bending change information of the sensor can be calculated in reverse. The sensor has been used by multiple scientific research units and currently does not provide algorithms.

Beijing Dacheng Yongsheng Technology Co., Ltd.:

Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS) is a professional manufacturer of fiber grating sensors, fiber grating demodulators and system software. Specializing in the production of various fiber grating sensors, including temperature, strain, stress, displacement, vibration, shape sensors, etc. DCYS also produces fiber grating demodulators, and can customize and develop related application software.

Recommended fiber grating demodulator:

Product Alias: Fiber Bragg Grating Interrogator, FBG Interrogator, FBG Sensor Interrogator, Fiber Optic Grating Interrogator, Fiber Bragg Grating Demodulator, FBG Demodulator, Fiber Optic Grating Demodulator

This product is produced by DCYS, and it is a high-speed high-frequency fiber Bragg grating demodulator(Interrogator). The fiber grating demodulator is compatible with various specifications and models of OFSCN® fiber bragg grating sensors (temperature, strain, stress FBG sensors, etc.). It features adjustable port density (4, 8, 16 channels) and high-speed high-refresh rate capabilities.

DCYS Helps to Monitor Angle, Curvature and Shape Sensing of Robots

With our expertise in fiber grating sensing technology, DCYS can help solve some problems in robot technology for shape sensing monitoring of robots.

Other Points Need to Be Clarified:

In conclusion, fiber grating sensing technology has shown great potential in shape sensing monitoring of robots, addressing the challenges of accurate and reliable shape sensing in robotic applications. With the help of fiber grating shape sensors and demodulators, robots can be equipped with precise and real-time shape sensing capabilities, enabling them to operate in complex and dynamic environments with higher efficiency and safety. Beijing Dacheng Yongsheng Technology Co., Ltd. has a wealth of experience in the production of fiber grating sensors and demodulators, and can provide customized solutions and software development services for customers in the field of robotics. As the technology continues to evolve, fiber grating sensing technology is poised to play an even greater role in shaping the future of robotics.