Application of Fiber Bragg Grating Sensing Technology - Application of FBG Sensor - Application of FBG-Application of FBG Demodulator - Application of FBG Sensing in Industry

FBG Sensing Technology for the Temperature Monitoring of Gas Liquefaction Process

Fiber grating sensing technology has gained significant attention in various fields, including scientific research. In scientific research, temperature monitoring is a critical aspect in various processes, including gas liquefaction. Gas liquefaction is a process that involves cooling and pressurizing gas to convert it into a liquid state. Accurate temperature monitoring is essential in this process to ensure that it is efficient, safe, and effective. In this article, we will discuss the problems that fiber grating sensing technology can solve, and how Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS ) can support the temperature monitoring of gas liquefaction process.

Fiber Bragg Grating Sensing Principle:

Fiber Bragg gratings (FBGs) are periodic structures that are inscribed in the core of an optical fiber. These structures reflect a specific wavelength of light that is determined by the periodicity of the grating. When the grating is subjected to mechanical or thermal strain, the reflected wavelength changes in a predictable manner. By monitoring the reflected wavelength, changes in strain, temperature, and other parameters can be detected. FBG sensors can be used to monitor a wide range of parameters, including strain, stress, temperature, and vibration.

Click the link below for more details:

Analysis of Demand for Temperature Monitoring of Gas Liquefaction Process:

Gas liquefaction is a critical process in various fields, including scientific research, energy production, and industrial processes. In scientific research, gas liquefaction is essential for studying the properties and behavior of gases at low temperatures. Accurate temperature monitoring is crucial in this process to ensure that the gas is converted into a liquid state efficiently, safely, and effectively.

Why Temperature Monitoring of Gas Liquefaction Process is Needed:

Temperature monitoring of gas liquefaction processes is essential in scientific research to understand the properties and behavior of gases at low temperatures. Gas liquefaction is used to study the properties of gases in various fields, including materials science, condensed matter physics, and chemistry. By monitoring the temperature during the gas liquefaction process, it is possible to obtain accurate data on the behavior of gases at low temperatures, which is critical in advancing scientific knowledge in various fields.

Difficulties in Temperature Monitoring of Gas Liquefaction Process:

Temperature monitoring of gas liquefaction processes in scientific research can be challenging due to several factors. The low temperatures involved in the process make it difficult to use traditional temperature measurement techniques, which may not be accurate or reliable. Additionally, the harsh conditions involved in the gas liquefaction process, including high pressure and extreme temperatures, make it challenging to use conventional temperature sensors.

What Problems can be Solved by FBG Sensing Technology:

Fiber grating sensing technology offers several advantages for temperature monitoring in gas liquefaction processes. Unlike traditional temperature measurement techniques, fiber grating sensing technology is not affected by the extreme conditions involved in the process, making it a reliable and accurate method for temperature monitoring. Additionally, fiber grating sensors are small, lightweight, and flexible, making them easy to install and operate in the confined spaces involved in the gas liquefaction process. Finally, fiber grating sensors are immune to electromagnetic interference, which is critical in scientific research where accurate data is essential.

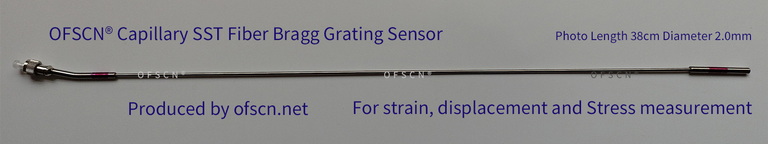

Recommended fiber grating temperature sensors:

Beijing Dacheng Yongsheng Technology Co., Ltd.:

Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS) is a professional manufacturer of fiber grating sensors, fiber grating demodulators and system software. Specializing in the production of various fiber grating sensors, including temperature, strain, stress, displacement, vibration, shape sensors, etc. DCYS also produces fiber grating demodulators, and can customize and develop related application software.

Recommended fiber grating demodulator:

Product Alias: Fiber Bragg Grating Interrogator, FBG Interrogator, FBG Sensor Interrogator, Fiber Optic Grating Interrogator, Fiber Bragg Grating Demodulator, FBG Demodulator, Fiber Optic Grating Demodulator

This product is produced by DCYS, and it is a high-speed high-frequency fiber Bragg grating demodulator(Interrogator). The fiber grating demodulator is compatible with various specifications and models of OFSCN® fiber bragg grating sensors (temperature, strain, stress FBG sensors, etc.). It features adjustable port density (4, 8, 16 channels) and high-speed high-refresh rate capabilities.

DCYS Helps to Monitor the Temperature of Gas Liquefaction Process:

DCYS can help solve some problems in the scientific research field of temperature monitoring of the gas liquefaction process. By providing reliable and accurate fiber grating sensors and demodulators, DCYS can ensure that the temperature monitoring in gas liquefaction processes is efficient, safe, and effective. Additionally, DCYS's expertise in developing customized application software can help researchers in scientific research to obtain accurate and reliable data.

Other Points Need to Be Clarified:

In addition to temperature monitoring, fiber grating sensing technology can also be used to monitor other physical parameters in gas liquefaction processes, including pressure and strain. By monitoring these physical parameters, it is possible to obtain a comprehensive understanding of the behavior of gases at low temperatures, which is critical in advancing scientific knowledge in various fields.

In conclusion, fiber grating sensing technology offers significant advantages in temperature monitoring of gas liquefaction processes in scientific research. Accurate temperature monitoring is crucial in gas liquefaction processes to ensure that the gas is converted into a liquid state efficiently, safely, and effectively. By providing reliable and accurate fiber grating sensors and demodulators, Beijing Dacheng Yongsheng Technology Co., Ltd. can help solve some of the problems involved in temperature monitoring in gas liquefaction processes. The application of fiber grating sensing technology in scientific research offers great potential in advancing scientific knowledge in various fields, including materials science, condensed matter physics, and chemistry.