Fiber Bragg Grating Sensing Technology Encyclopedia - FBG FAQ - FBG Sensor FAQ - FBG Demodulator FAQ - FBG Common Application Problem Analysis

Is the Fiber Grating Sensor can be used in Water?-Waterproof & Moisture-proof FBG Sensor-Moisture, Humidity, Liquid Environment

This article discusses the influence of moisture, humidity, and water on traditional FBG sensors, including their effects on the sensor's lifespan and testing accuracy (which is one of the disadvantages of traditional FBG sensors).

It also introduces the innovative use of a fully-metallic FBG packaging structure in the OFSCN® Capillary Seamless Steel Tube FBG Sensors. This design effectively avoids the negative effects of moisture, humidity, and water on the FBG sensors (temperature, strain, and stress), allowing them to be used directly underwater and in liquid environments. These sensors are waterproof FBG sensors.

1. The Impact of Moisture and Water on Traditional Fiber Bragg Grating Sensors

|

|

Figure 1 |

For most traditional FBG sensors, moisture, humidity, and water are harmful. These sensors typically use various types of adhesives and glues to enclose and fix the optical fiber or FBG, and these materials gradually become unstable under the influence of moisture, humidity, and water, thereby shortening the lifespan of traditional FBG sensors (as shown in Figure 1).

Additionally, moisture, humidity, and water can cause the expansion of materials used in the traditional packaging of FBG sensors. This expansion affects the stress and strain of the FBG, which has a significant negative impact on the measurements we require (whether it's temperature, strain, or stress).

2. Reasons and Applications of Waterproof and Moisture-Proof OFSCN® Capillary Seamless Steel Tube Fiber Bragg Sensors

|

|

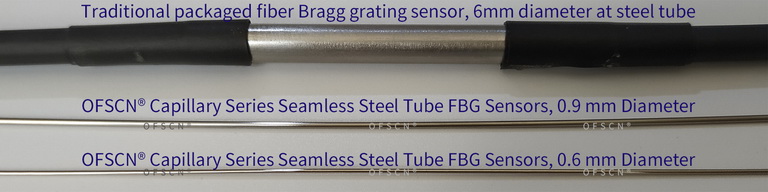

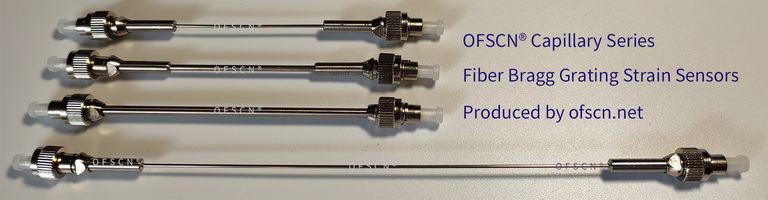

Figure 2 |

OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Sensors (FBG stress, strain, and temperature sensors) from DCYS uses a unique stainless steel seamless tube patented packaging technology (fully metallic appearance), providing comprehensive protection for the FBG.

Moreover, the single-ended OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensors (FBG stress, strain, and temperature sensors) have a glue-free design, with only optical fiber, FBG, and stainless steel components. Therefore, they are completely unaffected by moisture, humidity, and water, allowing direct use in water and mildly corrosive liquids (see Figure 1, 3, 4).

The double-ended OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Sensors (FBG stress, strain, and temperature probes) can be directly embedded in concrete after adding additional joint sealing. They are also unaffected by moisture, humidity, and water (see Figure 2).

|

|

|

Figure 3 |

Figure 4 |

Our philosophy is: "OFSCN®, make optical fiber stronger!"

DCYS is a professional manufacturer of waterproof fiber bragg grating sensors, providing waterproof and moisture-proof FBG temperature sensors, FBG strain sensors used in liquid environments, underwater FBG stress sensors, advantages of FBG sensors and other information; The waterproof FBG sensor brand is "OFSCN".