Fiber Bragg Grating Sensing Technology Encyclopedia - FBG FAQ - FBG Sensor FAQ - FBG Demodulator FAQ - FBG Common Application Problem Analysis

Tensile Resistance of FBG Sensor- Ranging from 400 Newtons to 10,000 Newtons - High Tensile Resistance and Easy Installation Deployment

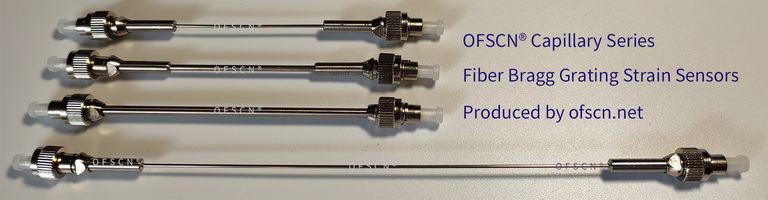

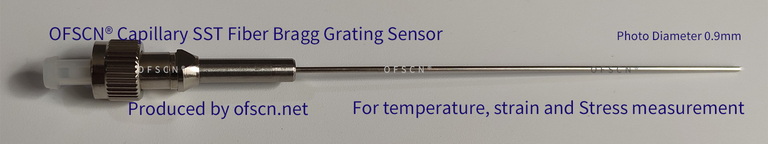

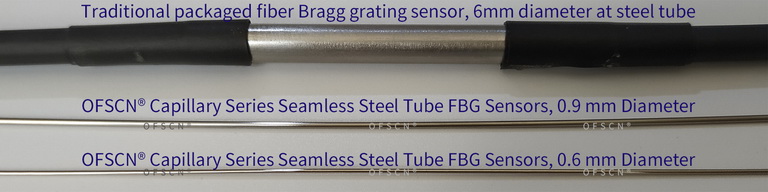

This article analyzes the advantages and application benefits brought by the high tensile strength of FBG sensors, including the extension of application environments and the convenience of engineering construction. It also introduces the "OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensor" produced by DCYS, highlighting its high tensile strength and specific characteristics for temperature, strain, and stress measurements. Partial physical images are provided as well.

1. Structure and Advantages of High Tensile Fiber Bragg Grating Sensors (FBG sensors, FBG probes)

It is evident that the tensile performance has an impact on the engineering construction and the long-term normal use of FBG sensors (FBG probes). Below, we will briefly analyze it from the perspective of tensile capacity.

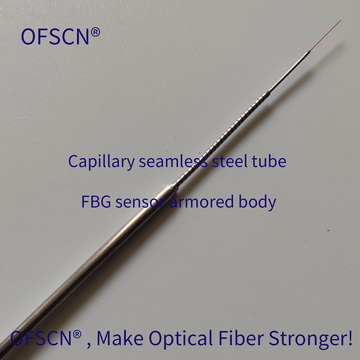

The body of OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensors (FBG sensors, FBG probes) is made of stainless steel, benefiting from the characteristics of this material. Therefore, they possess high tensile strength.

|

|

|

Figure 1 |

Figure 2 |

2. Tensile Strength of OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensors (FBG sensors, FBG probes)

The main body of the standard OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Sensors (FBG sensors, FBG probes) has an outer diameter of 0.9 millimeters and a wall thickness of 0.18 millimeters (see Figure 1 and 2). Based on our calculations and measurements, the main body of the grating sensor can withstand a tensile force exceeding 650 Newtons. We have determined a safe tensile strength of over 400 Newtons for practical use, which, in simpler terms, is equivalent to lifting a weight of 40 kilograms using this sensor.

|

|

Figure 3 |

|

| Figure 4 |

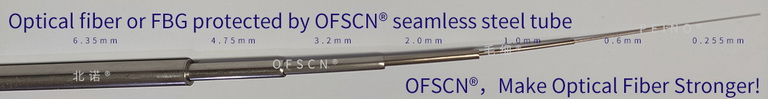

The tensile strength of the grating sensor can be adjusted by modifying the diameter and wall thickness of the stainless steel seamless tube in OFSCN® Capillary® Seamless Steel Tube Series FBG Stress Sensors (FBG tensile gauges, FBG pressure gauges) and Strain Sensors (FBG strain gauges) (see Figure 3 and 4). Additionally, the tensile strength of the grating sensor can be adjusted by nesting multiple layers of steel tubes and other structural elements (see Figure 5 and 6).

By using larger diameter and thicker-walled stainless steel seamless tubes, OFSCN can provide grating sensors with a tensile strength exceeding 10,000 Newtons (yes, the "0" is correct, and it can have even more digits if required).

|

|

Figure 5 |

|

| Figure 6 |

3. Applications and Construction Advantages of OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensors (FBG sensors, FBG probes) with High Tensile Strength

DCYS produces "OFSCN® Capillary Seamless Steel Tube Series FBG Sensors" using a unique patented structure, which exhibits higher strength compared to traditional FBG sensors.

Although the optical fiber cable of traditional FBG sensors has relatively good tensile strength, the connection between the stainless steel tube and the optical fiber cable is the weakest part of the entire grating sensor. This vulnerability can be compared to the shortest plank in the well-known "barrel theory," greatly reducing the overall tensile strength. Unfortunately, we cannot provide specific numerical values as DCYS has not conducted relevant tests.

|

|

The high tensile strength of OFSCN® Capillary Seamless Steel Tube FBG Sensors primarily manifests as advantages in engineering construction. The high tensile strength directly reduces the difficulty and losses in construction for contractors, thus lowering the installation cost of the sensors.

In the past, the installation and deployment of traditional fiber optic grating sensors were considered cumbersome and required skilled workers with years of experience to handle them carefully. However, with the higher tensile strength of OFSCN® Capillary Seamless Steel Tube FBG Sensors, ordinary workers can now participate in the construction as long as they meet the minimum bending radius requirements of the sensors. The sensors are less prone to damage.

Our philosophy is: "OFSCN®, make optical fiber stronger!"

DCYS is a professional high-strength FBG sensor manufacturer, providing information such as tensile FBG temperature sensors, strong FBG strain sensors, high tensile FBG stress sensors, advantages of FBG sensors, etc.; The brand of fiber bragg grating sensor is "OFSCN".