Fiber Bragg Grating Sensing Technology Encyclopedia - FBG FAQ - FBG Sensor FAQ - FBG Demodulator FAQ - FBG Common Application Problem Analysis

Installation Method of FBG Sensor- The Maintenance Advantage of Light Weight- FBG Sensor with the Lightest Weight 1.7g/m

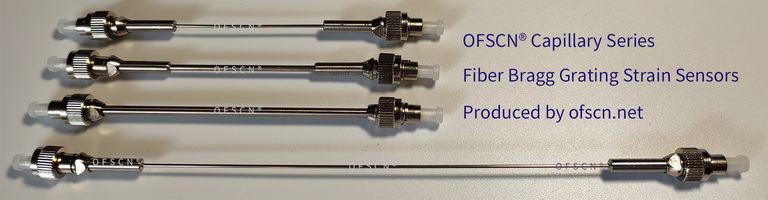

This article introduces the advantages and benefits brought by the lightweight nature of fiber bragg grating (FBG) sensors, including the expansion of application environments and convenience in engineering construction. It also introduces OFSCN® seamless steel tube series FBG sensors produced by DCYS. The sensors produced by DCYS have the advantages and characteristics of light weight, so they can be used for temperature, strain or stress measurement. It also shows some physical diagrams.

1. The Structure and Weight Calculation of the Light-weight Fiber Bragg Grating Sensor (FBG Sensor) (FBG probe)

Corresponding to their small size, the "OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensors produced by DCYS have very light weight.

|

|

| Figure 1 |

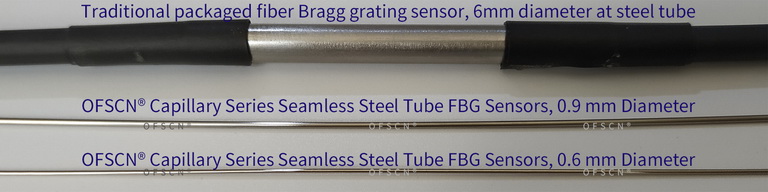

Figure 2 |

From basic physics, we know that weight or mass is related to material density and volume (the calculation formula for mass is M=pv). In the case where the material is already determined (stainless steel), the smaller the volume, the lighter the weight.

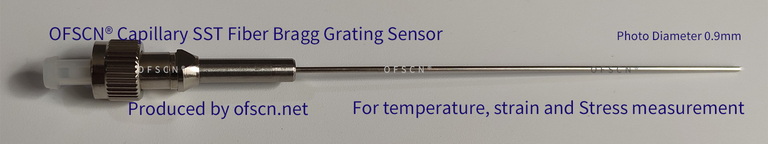

The OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensor is precisely a type of fiber bragg grating sensor (FBG sensor) with an extremely small volume. The outer diameter of the main body of the standard product is only 0.9 millimeters (see Figure 1, Figure 2, and Figure 3 below).

Through our calculations and laboratory measurements, the weight of the main body of the grating sensor is approximately 3.2 grams per meter. In other words, a 2-meter long OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensor (FBG sensor) without the connector weighs only 6 grams. This is in stark contrast to the significant weight of traditional fiber bragg grating sensors.

|

|

Figure 3 |

2. Application and Construction Advantages of Lightweight for OFSCN® Capillary Seamless Steel Tube Series Fiber Bragg Grating Sensors (FBG Probes)

The lightweight nature of fiber bragg grating sensors has a similar impact on sensing measurements as their small size. The lighter the weight (the smaller the volume) of the sensor, the easier it is to tightly integrate it with the measured structure. This also minimizes the impact on the measured structure, allowing for more accurate reflection of the physical properties of the object being measured (Reference: "Benefits of Small Size for Fiber Bragg Grating Sensors")

|

|

Figure 4 |

For example, if you need to test the thermal performance of a down jacket, you may need to place a fiber bragg grating temperature sensor (FBG thermometer) between the down feathers of the jacket. If you use a traditional fiber bragg grating sensor, its large size may displace the feathers during placement, and its heavy weight may compress the feathers, causing significant structural changes in the object being measured. How can we claim the measurement results to be accurate under such circumstances?

However, if you switch to the OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating Sensor (FBG probe), its small size and lightweight nature minimize the impact on the object being measured, resulting in more accurate test results.

|

| Figure 5 |

Our philosophy is: "OFSCN®, make optical fiber stronger!"

DCYS is a professional manufacturer of ultra-light fiber bragg grating sensors, providing information on light FBG temperature sensors, high-strength FBG strain sensors, capillary FBG stress sensors, advantages of FBG sensors, etc.; light weight FBG sensor brand is "OFSCN".