FBG sensor calibration - FBG temperature strain force weight displacement sensor - factory report - concept principle coefficient function formula - calibration service

Table of Contents:

Ⅰ. What is Fiber Bragg Grating Sensor Calibration?

Fiber Bragg Grating (FBG) sensor calibration refers to the process of establishing the correspondence or relationship (calibration formula) between the FBG wavelength information obtained from the FBG demodulator/interrogator or FBG sensing analyzer and the actual physical quantity to be measured. The calibration may involve various parameters, such as FBG wavelength-temperature, FBG wavelength-strain, FBG wavelength-displacement, FBG wavelength-force, FBG wavelength-acceleration, FBG wavelength-vibration, FBG wavelength-angle, FBG wavelength-weight, FBG wavelength-current, etc. Specialized equipment and calibration experiments are required to complete the calibration process of FBG sensors.

Ⅱ. Why is Calibration Necessary for Fiber Bragg Grating Sensors?

Fiber Bragg Grating demodulator/interrogators or FBG sensing analyzers can only recognize wavelength signals. However, wavelength information alone is not meaningful for the physical quantity we want to measure. We must establish the corresponding relationship or link (calibration formula) between the FBG wavelength signal and the physical quantity to be measured. This relationship or link (calibration formula) can only be determined through calibration experiments. Therefore, FBG sensors must undergo calibration before leaving the factory.

Ⅲ. Calibration and Temperature Coefficient of Fiber Bragg Grating Temperature Sensors

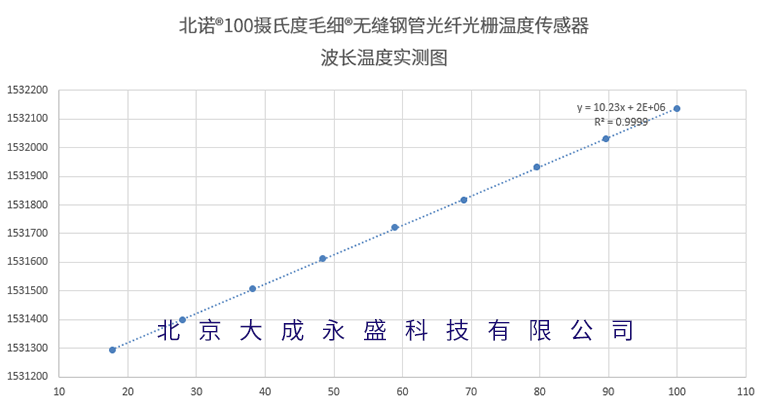

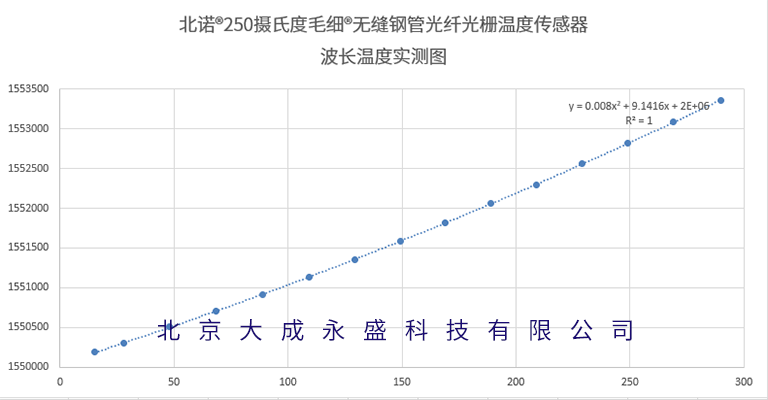

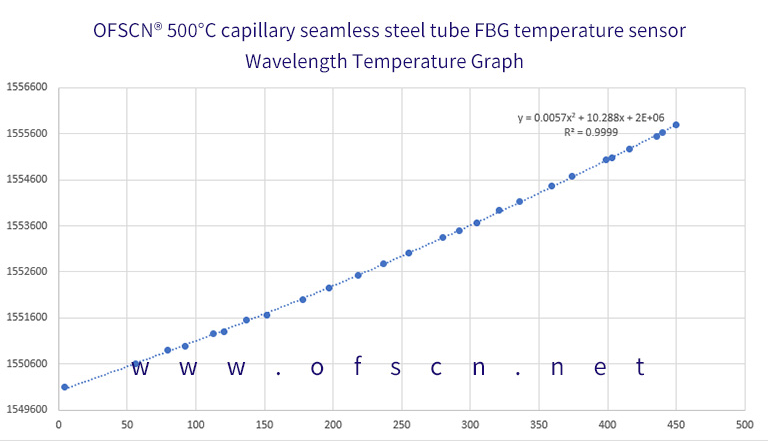

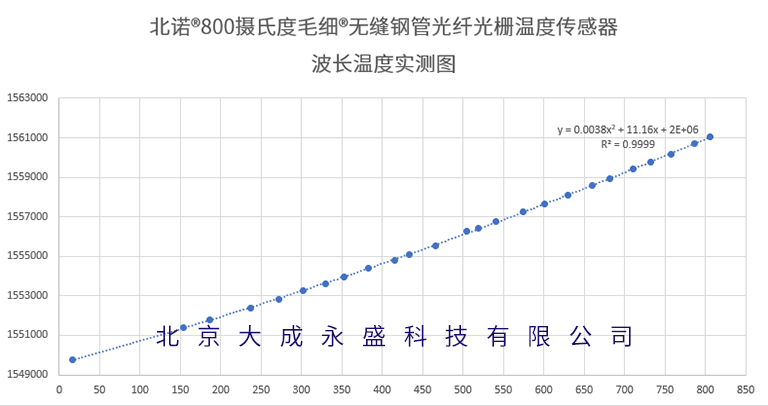

Below, we provide sample calibration reports for some OFSCN® capillary series seamless steel tube FBG temperature sensors (FBG thermometers) produced by DCYS. These reports also include the temperature coefficients, also known as temperature functions, temperature curves, or wavelength-temperature formulas.

OFSCN® 100-degree Celsius capillary seamless steel tube fiber bragg grating (FBG) temperature sensors (FBG thermometers) produced by DCYS undergo calibration during the manufacturing process. They are accompanied by the basic temperature coefficient (also known as calibration coefficient or calibration function) of the fiber bragg grating sensor. The following is a brief description of the calibration of this product:

OFSCN® 300°C Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensors (FBG Thermometers) produced by DCYS undergo calibration before leaving the factory, and the basic temperature coefficients (also known as calibration coefficients or calibration functions) for the fiber bragg grating sensors are provided along with the product. Here is a brief explanation of the calibration for this product:

OFSCN® 500°C Capillary Seamless Steel Tube Fiber Bragg Grating Temperature Sensors (FBG Thermometers) produced by DCYS undergo calibration before leaving the factory, and the basic temperature coefficients (also known as calibration coefficients or calibration functions) for the fiber bragg grating sensors are provided along with the product. Here is a brief explanation of the calibration for this product:

The OFSCN® 800°C Capillary Seamless Steel Tube Fiber Bragg Grating temperature sensor (FBG thermometer) , manufactured by DCYS, undergoes temperature calibration before leaving the factory. Along with the product, basic temperature coefficients (also known as calibration coefficients or calibration functions) of the fiber optic grating sensor are provided. The following is a brief description of the temperature calibration of the product at the time of shipment:

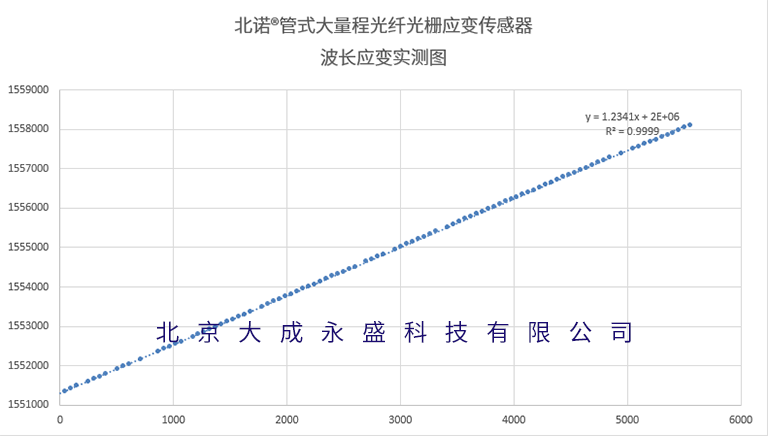

Ⅳ. Calibration and Strain Coefficient of Fiber Bragg Grating Strain Sensors

The factory calibration and strain coefficients of Fiber Bragg Grating strain sensors, also known as FBG strain functions, strain curves, strain sensitivity coefficients, or wavelength-strain formulas.

The OFSCN® fiber bagg grating strain sensor (FBG strain gauge) produced by DCYS is calibrated at the factory and comes with the basic strain coefficient and temperature coefficient (also known as calibration coefficient or calibration function) of the fiber bragg grating sensor. Below is a brief description of the calibration of the strain coefficient of the fiber bragg grating strain sensor with a range of 10,000 microstrains at the factory:

Ⅴ. Calibration and Length Coefficient of Fiber Bragg Grating Displacement Sensors

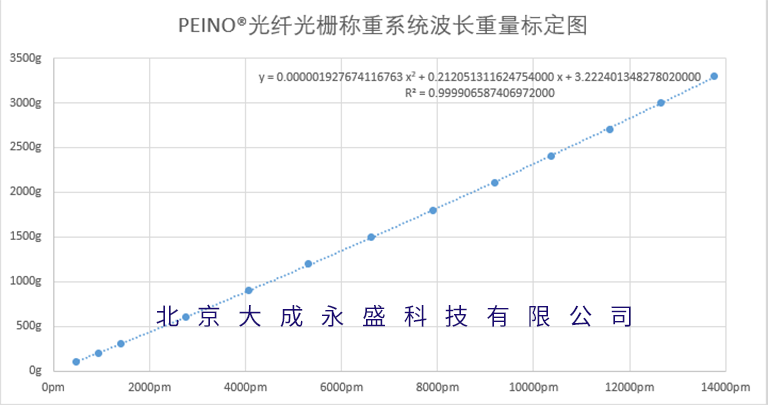

Ⅵ. Calibration and Weight Coefficient of Fiber Bragg Grating Weighing Systems

The factory calibration and weight coefficients of Fiber Bragg Grating weighing sensors, also known as FBG weight functions, weight curves, or wavelength-weight formulas.

Principle of the Fiber Bragg Grating Weighing System:

The OFSCN® fiber Bragg grating weighing system (force measurement system) is an application of the Dacheng Yongsheng fiber Bragg grating strain sensor. By utilizing the wavelength change of the sensing element, FBG fiber Bragg grating in OFSCN® fiber Bragg grating strain sensor, corresponding to the weight and force, it can realize real-time online monitoring and recording of weight and force of the measured object.

Ⅶ. Calibration and Tensile Force Coefficient of Fiber Bragg Grating Force Measurement Systems

Ⅷ. Calibration and Recalibration of Fiber Bragg Grating Sensors

All types of OFSCN® FBG sensors produced by DCYS, usually undergo calibration before leaving the factory (unless the customer specifically requests no calibration). In the case of long-term use or occasional overloading of the FBG sensor without damage, the sensor may become inaccurate. In such cases, the sensor can be recalibrated, which means providing a secondary calibration or re-calibration service.

Ⅸ. Fiber Bragg Grating Sensor Calibration Experiment Process, Methods, Apparatus, and Experimental Report.

This page also provides a detailed process of the calibration experiment for OFSCN® FBG temperature sensors, including calibration methods, experimental setups, and an experimental report with error analysis. Please refer to the provided link for more information.