Fiber Bragg Grating Sensing Technology Encyclopedia - FBG FAQ - FBG Sensor FAQ - FBG Demodulator FAQ - FBG Common Application Problem Analysis

Advantage Analysis of the Fiber Bragg Grating (FBG) Temperature Sensor- High Sensitivity FBG Thermometer

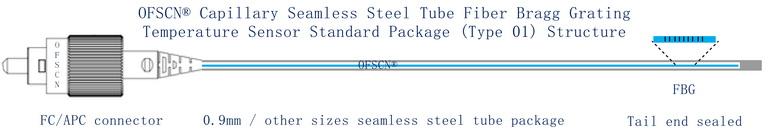

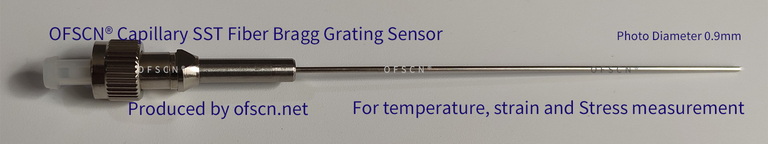

This article analyzes the high sensitivity characteristics of OFSCN® capillary seamless steel tube fiber bragg grating (FBG) sensor (thermometer) from a theoretical perspective. It discusses the influence of path length and temperature transmission medium (packaging material) on the sensitivity of the grating sensor, specifically focusing on the thermal conduction aspect of the packaging material for fiber bragg grating.

It highlights that the patented all-metal packaging structure and smaller size (volume) of OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensor are the fundamental reasons for its high sensitivity in encapsulating FBGs.

As stated on the official website of DCYS, "OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensor (FBG thermometer) has the characteristics of high sensitivity, fast thermal conduction, good accuracy, small size, light weight, high tensile strength, high compressive strength, high temperature resistance, waterproof and moisture-proof, non-combustible, and corrosion resistance." Today, we will focus on analyzing its high sensitivity characteristics.

1. Encapsulation Structure of OFSCN® Capillary Seamless Steel Tube Fiber Bragg Grating (FBG) Temperature Sensor

A typical OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensor (FBG thermometer) has a longitudinal structure as shown in Figure 1 and 2:

|

|

Figure 1 |

|

| Figure 2 |

Its cross-sectional profile at the tail end is shown in Figure 3 and 4:

|

|

|

Figure 3 |

Figure 4 |

The blue part shown in Figure 3 represents the fiber and fiber bragg grating, located at the center of the seamless steel tube. This diagram represents an ideal theoretical state, while in practical operation, the OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensor (FBG thermometer) takes on the actual state

2. Sensitivity of Fiber Bragg Grating in Fiber Bragg Grating Temperature Sensors

Undoubtedly, "bare" fiber bragg gratings (FBG) without any encapsulation exhibit the highest sensitivity in temperature measurement. However, due to the fragility of the fiber and fiber Bragg grating (FBG), bare fiber Bragg gratings are almost unusable in practical engineering applications and are only temporarily used in laboratory research. In practical operation, fiber bragg gratings (FBG) must be encapsulated, and all encapsulation methods will more or less reduce the sensitivity of the fiber bragg grating.

Therefore, when encapsulating fiber bragg grating (FBG) sensors, it is necessary to consider how to improve their sensitivity. Without the cooperation of sensors, the refresh rate of fiber bragg grating demodulation equipment would be meaningless. Even if the refresh rate of the fiber bragg grating demodulator reaches 5000 Hz, what use does it have? Can the temperature variation of the sensor reach 5000 times per second?

3. Packaging Material of OFSCN Micro Seamless Steel Tube Fiber Bragg Grating Temperature Sensor

The secret behind the high sensitivity of OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensor primarily lies in two aspects: the overall all-metal material characteristics and the unique product structure (sensor structure detailed in Figures 1, 2, 5, 6).

|

|

|

Figure 5 |

Figure 6 |

Whether it is the traditional fiber bragg grating temperature sensor (FBG thermometer) or OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensor (FBG thermometer), both use metal for encapsulating the FBG section. This is because metal has higher thermal conductivity than other materials. When the ambient environment or the temperature of the object being measured changes, heat can quickly transfer through the metal, accurately reflecting the external environment or the temperature of the object.

Unlike traditional fiber bragg grating temperature sensors (FBG thermometers), OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensors utilize only stainless steel material at the location of the FBG. They do not require adhesive to fix the fiber bragg grating, as heat can be transferred through the metal without the need for various adhesives.

Therefore, OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensors (FBG thermometers) have higher sensitivity. Higher sensitivity also implies more accurate temperature measurement and faster response speed.

4. Thermal Conduction Distance of Fiber Bragg Grating Temperature Sensors

Unlike traditional fiber bragg grating temperature sensors (fiber bragg grating thermometers), OFSCN® capillary seamless steel tube fiber bragg grating (FBG) temperature sensors (FBG thermometers) use smaller-sized stainless steel seamless tubes throughout. Smaller size means faster thermal conduction, which in turn leads to higher sensitivity and faster response speed.

Most importantly, when the external heat source has limited heat energy, the smaller size reduces heat dissipation and minimizes the impact of external measurement equipment on the object being measured. This is highly beneficial in many measurements and also means more accurate temperature measurement.

Our philosophy is: "OFSCN®, make optical fiber stronger!"

DCYS is a professional manufacturer of high-sensitivity optical fiber grating sensors, providing analysis of the advantages of fast response and rapid heat conduction of FBG sensors; the brand of high-sensitivity FBG sensors is "OFSCN".