Application of Fiber Bragg Grating Sensing Technology - Application of FBG Sensor - Application of FBG-Application of FBG Demodulator - Application of FBG Sensing in Industry

FBG Sensing Technology for Aircraft Structural Health Monitoring in Defense Industry

In the defense industry, aircraft structures are subject to a wide range of environmental stresses, including thermal, mechanical, and dynamic loads. These stresses can lead to material fatigue, corrosion, and other damage that can compromise the structural integrity of the aircraft. To ensure the safety and reliability of military aircraft, it is essential to monitor the health of aircraft structures continuously.

Fiber grating sensing technology has proven to be a powerful tool in various applications, including the health detection of aircraft structures in the defense industry. By monitoring changes in the structural integrity of aircraft components, fiber grating sensors can provide valuable information on the condition of the aircraft and help predict potential failures before they occur. In this article, we will provide an overview of the fiber grating sensing principle, challenges in aircraft structural health monitoring in the defense industry, how fiber grating sensing technology can help solve these problems,and how Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS ) can support aircraft structural health monitoring(SHM) in Defense Industry.

Fiber Bragg Grating Sensing Principle:

Fiber Bragg gratings (FBGs) are optical fibers with a periodic refractive index modulation that reflects a narrow bandwidth of light. When an FBG is subjected to an external stimulus, such as strain or temperature, the reflected wavelength shifts according to the stimulus. By monitoring the wavelength shift of the reflected light, FBGs can be used to measure a wide range of physical parameters, including strain, temperature, pressure, and vibration.

Click the link below for more details:

Challenges in Aircraft Structural Health Monitoring in the Defense Industry:

Structural health monitoring of aircraft structures in the defense industry is a challenging task due to the harsh operating environment, high levels of noise and vibration, and the need for real-time monitoring. Traditional monitoring techniques, such as strain gauges and accelerometers, are often inadequate due to their limited sensitivity and susceptibility to environmental noise. Additionally, the installation of these sensors can be time-consuming and costly, making it challenging to implement large-scale monitoring systems.

What Problems Can Be Solved by FBG Sensing Technology:

Fiber grating sensing technology can help overcome many of the challenges associated with aircraft structural health monitoring in the defense industry. FBG sensors are highly sensitive and can detect changes in the structural integrity of aircraft components with high accuracy. Additionally, the small size and flexibility of FBG sensors make them easy to install in a wide range of aircraft structures.

By monitoring changes in strain, temperature, and vibration, fiber grating sensors can provide valuable information on the condition of the aircraft structures. This information can be used to predict potential failures before they occur, allowing for timely maintenance and repair, reducing downtime, and improving the safety and reliability of military aircraft.

Recommended fiber grating strain sensors:

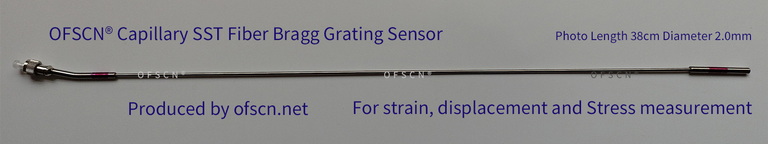

The product is a fiber Bragg grating strain sensor (FBG strain gauge) encapsulated in high elastic alloy tube, used for strain measurement. In most cases, it is a single-segment single-ended structures, or it can be produced as a multi-segment single-ended structure. In a few cases, it can also be a double-ended structure. The sensor can be customized as radiation-resistant fiber Bragg grating strain sensor or high-temperature resistant fiber Bragg grating strain sensor. The deployment method of the product depends on the supporting fixtures, which can be directly inserted into the test object, or installed by surface welding with corresponding fixtures, bolted with drilled holes for fixation, adhesive surface mounting, tied with straps for fixation, or fixed with clamps, among various installation methods. This product is a basic structural product, which can be calibrated as a FBG displacement sensor, or used as a FBG stress sensor.

OFSCN® 6000με FBG Strain Sensor Product Summary:

The OFSCN® 6000με FBG Strain Sensor (FBG strain gauge) is composed of fiber optic connectors (FC, SC, LC, ST, etc.), high elastic alloy tubes, and single-point/Multi-point FBG encapsulation.

It can also be customized as radiation-resistant FBG strain sensor or high-temperature resistant FBG strain sensor.

This product features a small size, lightweight, high tensile and compressive strength, waterproof, moisture-proof, and fully sealed characteristics. By utilizing the strain characteristics of the FBG, this sensor can be inserted, clamped, surface-mounted, glued, or embedded into the measured structure to perform strain detection and monitoring.

6000με Fiber Bragg Grating Strain Sensor - FBG Strain Gauge - polymer material packaging - metal protection strain sensor - range 6000με/8000μεThis product is a high-range fiber bragg grating strain sensor (FBG strain gauge) used for strain measurement. It can be used in a single-ended structure, where it is inserted into the object to be measured for strain measurement. It can also be used in a double-ended structure, where it is fixed with a fixture or bonded directly to the surface for strain measurement, enabling multi-point strain measurement when connected in series. The structure of this product is the same as that of fiber bragg grating stress sensors.

Product Overview:

The OFSCN® high-range fiber bragg grating strain sensor (FBG strain gauge) consists of fiber connectors (FC, SC, LC, ST, etc.), high elastic materials, and single-point FBG encapsulation. Depending on the materials used, it can work at room temperature or a maximum high temperature of 120 degrees Celsius (customizable upon request).

This product is characterized by its small size, light weight, high tensile and compressive strength, waterproof and moisture-proof properties, and full sealing. By utilizing the strain characteristics of FBG, this sensor can be inserted, welded, bonded, or adhered to the internal or surface of the test structure for strain detection and monitoring.

Beijing Dacheng Yongsheng Technology Co., Ltd.:

Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS) is a professional manufacturer of fiber grating sensors, fiber grating demodulators and system software. Specializing in the production of various fiber grating sensors, including temperature, strain, stress, displacement, vibration, shape sensors, etc. DCYS also produces fiber grating demodulators, and can customize and develop related application software.

Recommended fiber grating demodulator:

Product Alias: Fiber Bragg Grating Interrogator, FBG Interrogator, FBG Sensor Interrogator, Fiber Optic Grating Interrogator, Fiber Bragg Grating Demodulator, FBG Demodulator, Fiber Optic Grating Demodulator

This product is produced by DCYS, and it is a high-speed high-frequency fiber Bragg grating demodulator(Interrogator). The fiber grating demodulator is compatible with various specifications and models of OFSCN® fiber bragg grating sensors (temperature, strain, stress FBG sensors, etc.). It features adjustable port density (4, 8, 16 channels) and high-speed high-refresh rate capabilities.

DCYS Supports the Aircraft Structural Health Monitoring in Defense Industry:

DCYS can help the defense industry solve some problems in aircraft structural health monitoring by providing high-quality FBG sensors and demodulators, as well as customized software solutions. By working closely with the defense industry, DCYS can develop innovative solutions to meet the unique monitoring needs of military aircraft.

Other Points Need to Be Clarified:

In addition to structural health monitoring, fiber grating sensing technology can also be used for a wide range of other applications in the defense industry, including chemical and biological sensing, acoustic sensing, and optical fiber communication. As research continues, it is likely that even more applications for this technology will be discovered, making it an essential tool for the defense industry.

In conclusion, fiber grating sensing technology has proven to be a valuable asset in the health detection of aircraft structures in the defense industry. By providing high accuracy and sensitivity, FBG sensors can detect changes in strain, temperature, and vibration, which can help predict potential failures before they occur. Additionally, the small size and flexibility of FBG sensors make them easy to install in a wide range of aircraft structures.

Beijing Dacheng Yongsheng Technology Co., Ltd. (short for DCYS) is a professional manufacturer of fiber grating sensors, and we can help the defense industry overcome challenges associated with aircraft structural health monitoring by providing high-quality FBG sensors and demodulators, as well as customized software solutions. By working closely with the defense industry, DCYS can develop innovative solutions to meet the unique monitoring needs of military aircraft.

In summary, fiber grating sensing technology has revolutionized the way aircraft structural health monitoring is conducted in the defense industry. Its high accuracy, sensitivity, and flexibility make it an essential tool for ensuring the safety and reliability of military aircraft. As research continues, it is likely that even more applications for this technology will be discovered, further solidifying its place in the defense industry as a critical tool for aircraft health detection.