Application of Fiber Bragg Grating Sensing Technology - Application of FBG Sensor - Application of FBG-Application of FBG Demodulator - Application of FBG Sensing in Industry

FBG Sensing Technology for SHM of Mines in the Mining Industry

Structural health monitoring (SHM) is an essential process in the mining industry, which involves the use of sensors to monitor the structural integrity of mining equipment, tunnels, and shafts. Fiber grating sensing technology is one of the most advanced methods for SHM, providing accurate, real-time data on critical parameters such as temperature, strain, and deformation. This article will provide an overview of the principle of fiber grating sensing technology and its applications in SHM in the mining industry. In this article, we will discuss the problems that fiber grating sensing technology can solve, and how Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS ) can support the SHM in the mining industry.

Fiber Bragg Grating Sensing Principle:

Fiber Bragg gratings (FBGs) are periodic structures that are inscribed in the core of an optical fiber. These structures reflect a specific wavelength of light that is determined by the periodicity of the grating. When the grating is subjected to mechanical or thermal strain, the reflected wavelength changes in a predictable manner. By monitoring the reflected wavelength, changes in strain, temperature, and other parameters can be detected. FBG sensors can be used to monitor a wide range of parameters, including strain, stress, temperature, and vibration.

Click the link below for more details:

Analysis of Needs for SHM of Mines in the Mining Industry:

The mining industry is a high-risk environment where structural failures can have severe consequences. The constant exposure of mining equipment, tunnels, and shafts to harsh conditions such as vibration, high pressure, and temperature fluctuations, can cause damage and reduce their structural integrity over time. As a result, SHM is critical to identify potential structural problems and to take preventative measures to ensure the safety of mining personnel and equipment.

Why SHM of Mines in the Mining Industry is Needed:

The monitoring of mining equipment, tunnels, and shafts can help identify potential structural failures before they occur, preventing downtime, equipment damage, and personnel injury. By implementing SHM, mining operators can increase the lifespan of their equipment and reduce maintenance costs. Additionally, SHM can improve the efficiency and productivity of mining operations, resulting in increased profitability.

Difficulties in SHM of Mines in the Mining Industry:

The mining industry presents several challenges to the implementation of SHM. The harsh mining environment can interfere with sensor data, causing inaccurate readings. Additionally, the remote locations of many mining sites can make it challenging to install and maintain sensors, increasing costs and logistical difficulties. Furthermore, the underground nature of mining operations can present safety hazards to personnel installing and maintaining the sensors.

What Problems can be Solved by FBG Sensing Technology:

Fiber grating sensing technology provides several advantages over other SHM methods, making it an excellent solution for the mining industry. Fiber optic sensors are immune to electromagnetic interference, making them ideal for use in high-vibration environments. Additionally, fiber optic sensors are small and lightweight, making them easy to install in remote locations. The real-time data provided by fiber grating sensing technology can detect subtle changes in the structural integrity of mining equipment, tunnels, and shafts, allowing for prompt maintenance and repair.

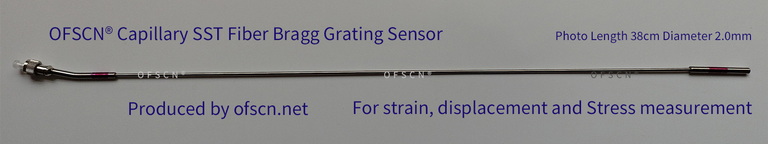

Recommended fiber grating strain sensers:

The product is a fiber Bragg grating strain sensor (FBG strain gauge) encapsulated in high elastic alloy tube, used for strain measurement. In most cases, it is a single-segment single-ended structures, or it can be produced as a multi-segment single-ended structure. In a few cases, it can also be a double-ended structure. The sensor can be customized as radiation-resistant fiber Bragg grating strain sensor or high-temperature resistant fiber Bragg grating strain sensor. The deployment method of the product depends on the supporting fixtures, which can be directly inserted into the test object, or installed by surface welding with corresponding fixtures, bolted with drilled holes for fixation, adhesive surface mounting, tied with straps for fixation, or fixed with clamps, among various installation methods. This product is a basic structural product, which can be calibrated as a FBG displacement sensor, or used as a FBG stress sensor.

OFSCN® 6000με FBG Strain Sensor Product Summary:

The OFSCN® 6000με FBG Strain Sensor (FBG strain gauge) is composed of fiber optic connectors (FC, SC, LC, ST, etc.), high elastic alloy tubes, and single-point/Multi-point FBG encapsulation.

It can also be customized as radiation-resistant FBG strain sensor or high-temperature resistant FBG strain sensor.

This product features a small size, lightweight, high tensile and compressive strength, waterproof, moisture-proof, and fully sealed characteristics. By utilizing the strain characteristics of the FBG, this sensor can be inserted, clamped, surface-mounted, glued, or embedded into the measured structure to perform strain detection and monitoring.

6000με Fiber Bragg Grating Strain Sensor - FBG Strain Gauge - polymer material packaging - metal protection strain sensor - range 6000με/8000μεThis product is a high-range fiber bragg grating strain sensor (FBG strain gauge) used for strain measurement. It can be used in a single-ended structure, where it is inserted into the object to be measured for strain measurement. It can also be used in a double-ended structure, where it is fixed with a fixture or bonded directly to the surface for strain measurement, enabling multi-point strain measurement when connected in series. The structure of this product is the same as that of fiber bragg grating stress sensors.

Product Overview:

The OFSCN® high-range fiber bragg grating strain sensor (FBG strain gauge) consists of fiber connectors (FC, SC, LC, ST, etc.), high elastic materials, and single-point FBG encapsulation. Depending on the materials used, it can work at room temperature or a maximum high temperature of 120 degrees Celsius (customizable upon request).

This product is characterized by its small size, light weight, high tensile and compressive strength, waterproof and moisture-proof properties, and full sealing. By utilizing the strain characteristics of FBG, this sensor can be inserted, welded, bonded, or adhered to the internal or surface of the test structure for strain detection and monitoring.

Beijing Dacheng Yongsheng Technology Co., Ltd.:

Beijing Dacheng Yongsheng Technology Co., Ltd.(short for DCYS) is a professional manufacturer of fiber grating sensors, fiber grating demodulators and system software. Specializing in the production of various fiber grating sensors, including temperature, strain, stress, displacement, vibration, shape sensors, etc. DCYS also produces fiber grating demodulators, and can customize and develop related application software.

Recommended fiber grating demodulator:

Product Alias: Fiber Bragg Grating Interrogator, FBG Interrogator, FBG Sensor Interrogator, Fiber Optic Grating Interrogator, Fiber Bragg Grating Demodulator, FBG Demodulator, Fiber Optic Grating Demodulator

This product is produced by DCYS, and it is a high-speed high-frequency fiber Bragg grating demodulator(Interrogator). The fiber grating demodulator is compatible with various specifications and models of OFSCN® fiber bragg grating sensors (temperature, strain, stress FBG sensors, etc.). It features adjustable port density (4, 8, 16 channels) and high-speed high-refresh rate capabilities.

DCYS Helps to do SHM of Mines in the Mining Industry:

With our expertise and experience, DCYS can help the hydropower industry to solve some of the challenges in the SHM of mines.

Other Points Need to Be Clarified:

Fiber grating sensing technology is a cutting-edge solution for SHM in the mining industry, providing real-time data that can prevent structural failures and ensure the safety of mining personnel and equipment. Furthermore, fiber grating sensing technology has the potential to improve the efficiency and profitability of mining operations by reducing downtime, maintenance costs, and increasing the lifespan of mining equipment.

Another significant advantage of fiber grating sensing technology is its ability to monitor multiple parameters simultaneously. This means that mining operators can obtain a comprehensive understanding of the structural health of their equipment, tunnels, and shafts, reducing the need for multiple sensors and increasing efficiency.

In addition to SHM, fiber grating sensing technology has numerous other applications in the mining industry. For example, it can be used for measuring the temperature and pressure of underground reservoirs, monitoring the stability of mining slopes, and detecting the presence of hazardous gases in mines.

In conclusion, fiber grating sensing technology is a valuable tool for SHM in the mining industry, providing accurate, real-time data on critical parameters such as temperature, strain, and deformation. With the expertise of Beijing Dacheng Yongsheng Technology Co., Ltd., mining operators can implement fiber grating sensing technology to improve the safety, efficiency, and profitability of their operations. As technology continues to advance, fiber grating sensing technology will undoubtedly play an increasingly critical role in the mining industry's future.